Amayunithi ethu egiya le-bevel ayatholakala ngebanga losayizi nokucushwa ukuze ahambisane nezinhlelo zokusebenza zemishini esindayo.Kungakhathaliseki ukuthi udinga iyunithi yegiya elihlangene yesilayishi se-skid steer noma iyunithi yetorque ephezulu yeloli yokulahla, sinesixazululo esifanele sezidingo zakho.Siphinde sinikeze imiklamo yangokwezifiso kanye nezinsizakalo zobunjiniyela zezinhlelo zokusebenza ezihlukile noma ezikhethekile, siqinisekisa ukuthi uthola iyunithi yegiya efanelekile yemishini yakho esindayo.

Hlobo luni lwemibiko ezonikezwa amakhasimende ngaphambi kokuthunyelwa ukuze kugaywe amagiya amakhulu e-spiral bevel?

1) Umdwebo webhamuza

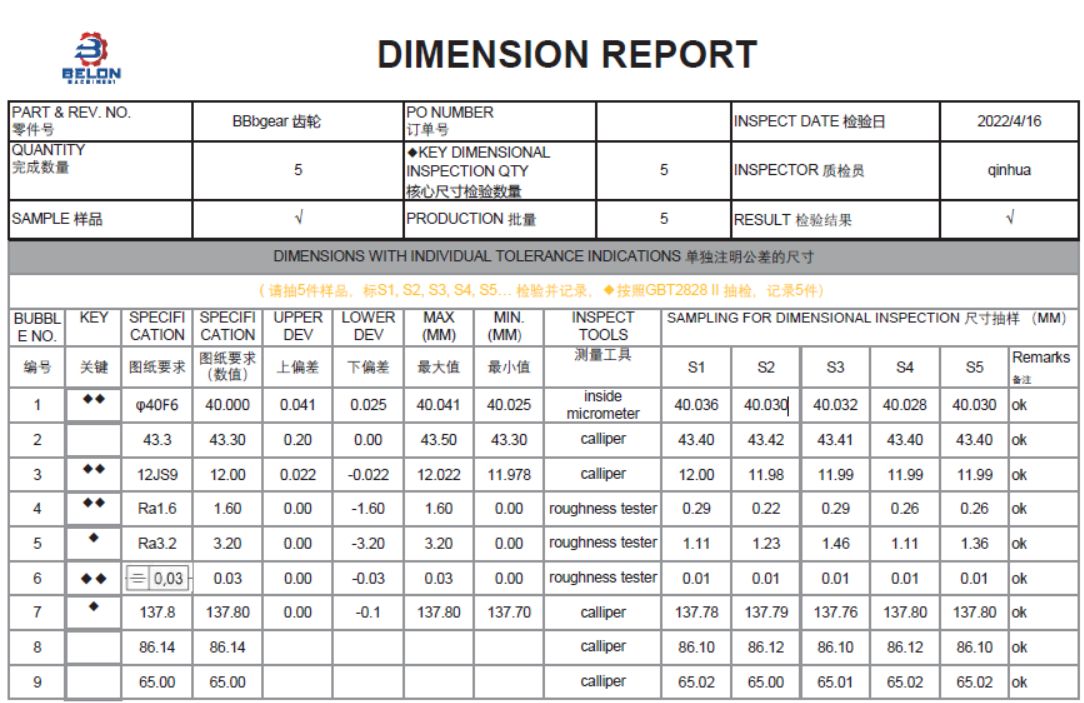

2) Umbiko wobukhulu

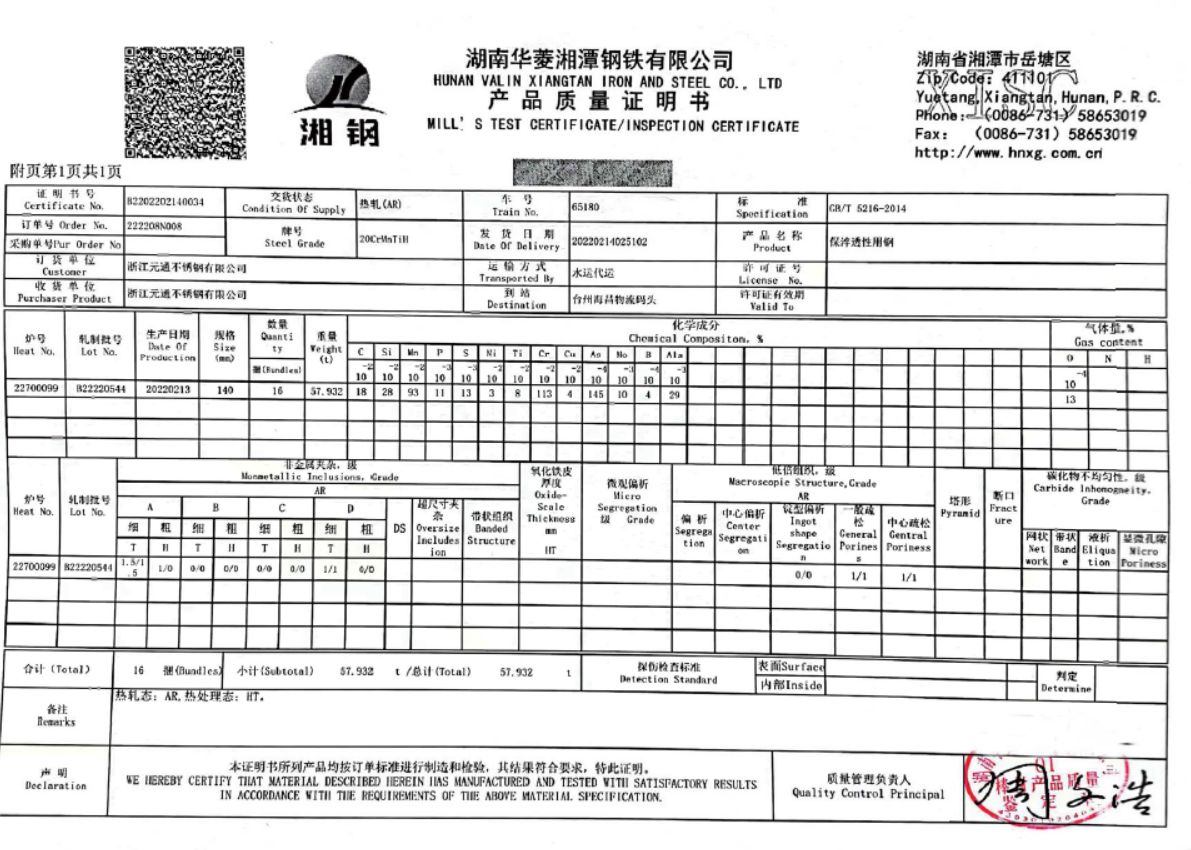

3) Isitifiketi sezinto ezibonakalayo

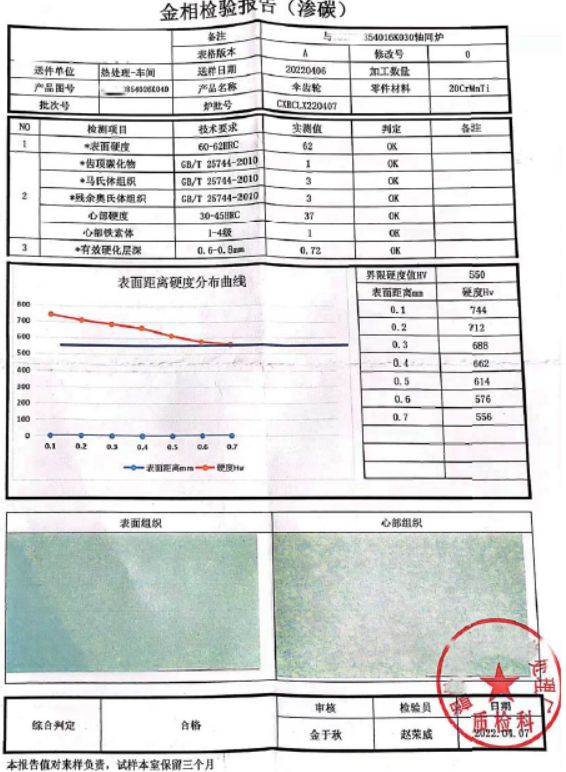

I-4) Umbiko wokwelashwa kokushisa

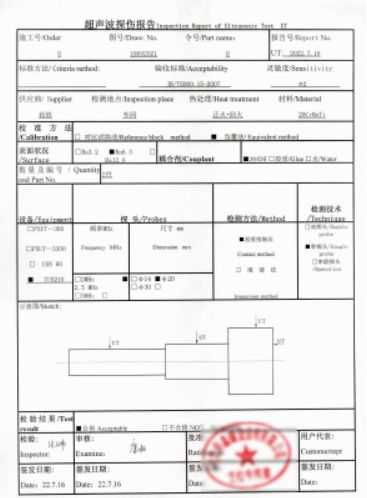

5) Umbiko wokuhlolwa kwe-Ultrasonic (UT)

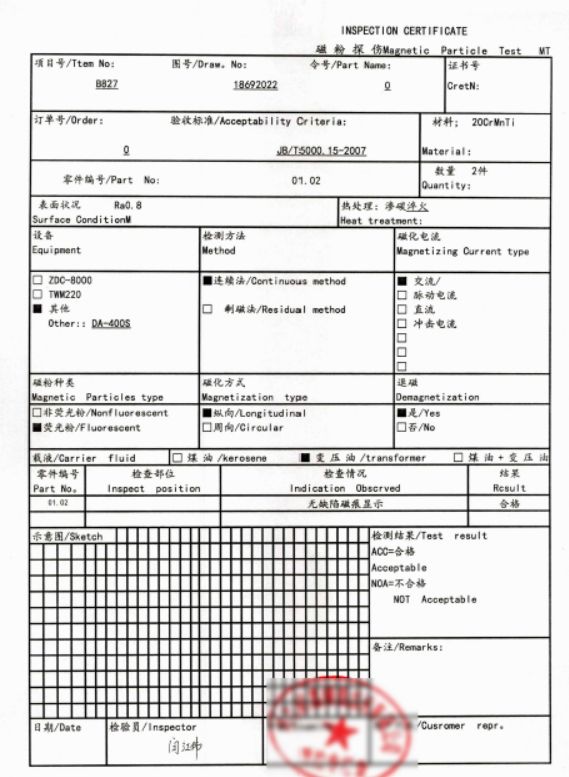

6) Umbiko wokuhlolwa kwe-Magnetic Particle (MT)

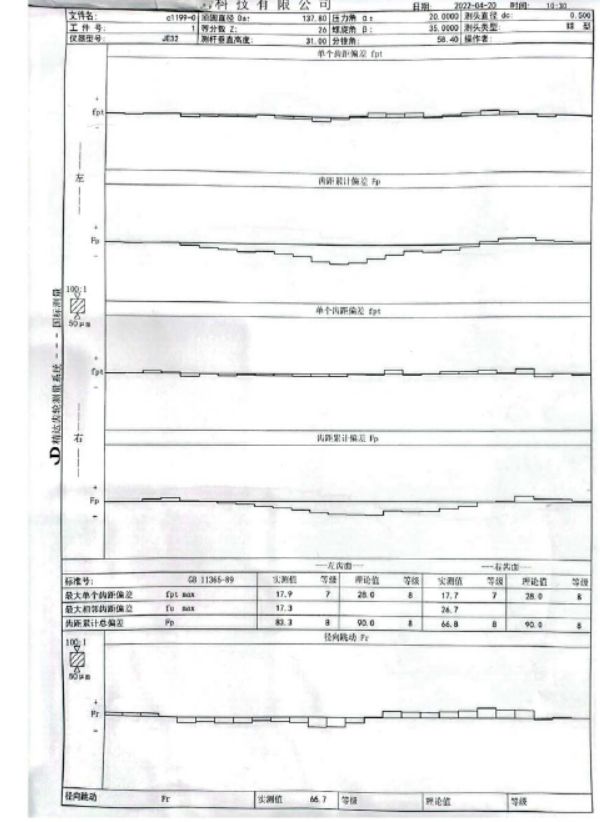

Umbiko wokuhlola we-Meshing

Sixoxa indawo engamamitha-skwele angu-200000, futhi efakwe kusengaphambili ukukhiqiza kanye nemishini yokuhlola ukuhlangabezana nesidingo samakhasimende.Sethule usayizi omkhulu kunawo wonke, isikhungo sokuqala semishini sase-China esiqondene ngqo negiya i-Gleason FT16000 selokhu kwaba nokubambisana phakathi kwe-Gleason ne-Holler.

→ Noma Yimaphi Amamojula

→ Noma yiziphi Izinombolo Zamazinyo

→ Ukunemba okuphezulu kwe-DIN5

→ Ukusebenza kahle okuphezulu, ukunemba okuphezulu

Ukuletha ukukhiqiza kwephupho, ukuguquguquka kanye nomnotho weqoqo elincane.

impahla eluhlaza

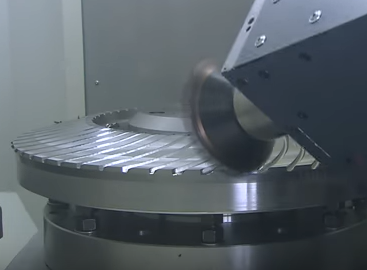

ukusika rough

ukuphenduka

ukuphefumula nokuphefumula

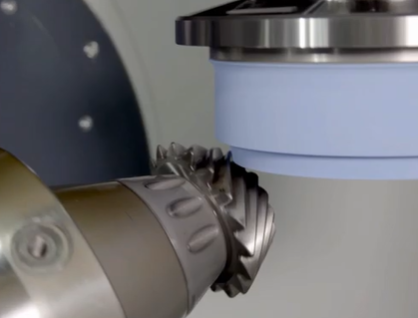

ukugaya amagiya

Ukuphatha ukushisa

ukugaya amagiya

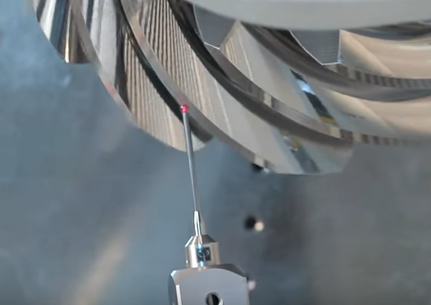

ukuhlola