Amandla Aphakeme I-Bevel Gearskuyisinqumo esihle kakhulu uma ufuna ukudluliswa okuthembekile nokunembile kwe-90 degree. Enziwe ngensimbi yekhwalithi ephezulu engu-45#, lawa magiya aqinile futhi aklanyelwe ukunikeza ukusebenza kahle nokunemba kokudluliswa kwamandla.

Ngezicelo zezimboni ezidinga ukudluliswa okunembile nokuthembekile kwe-90-degree,amagiya e-bevel aphezuluziyisixazululo esifanele. Lawa magiya enziwe ngendlela efanele ukuqinisekisa ukusebenza okuphezulu nokuqinisekisa ukusebenza kahle nangempumelelo.

Noma ngabe wakha imishini noma usebenza ngemishini yezimboni, lawa magiya e-bevel alungile. Kulula ukuzifaka nokusebenza, futhi zingamelana nezimo zezimboni ezinzima kakhulu.

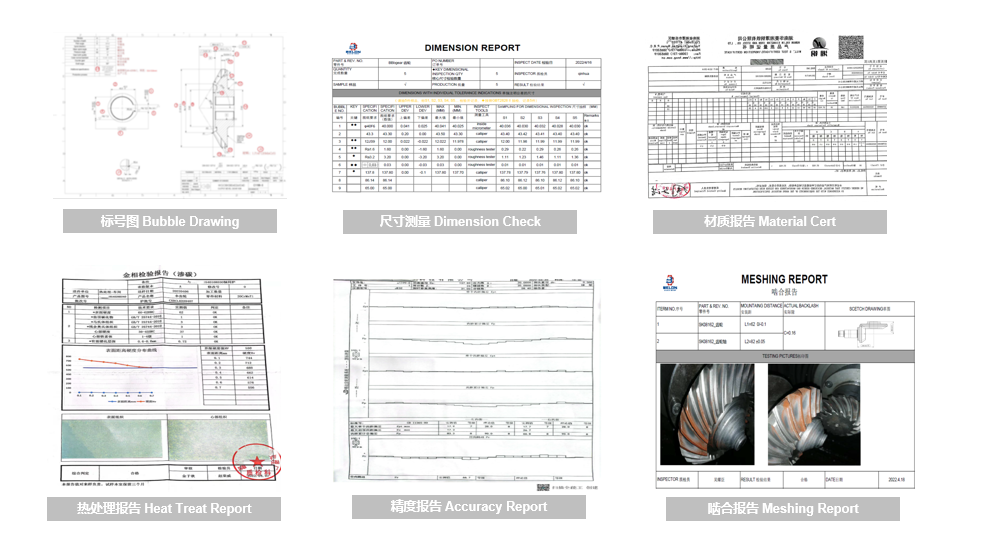

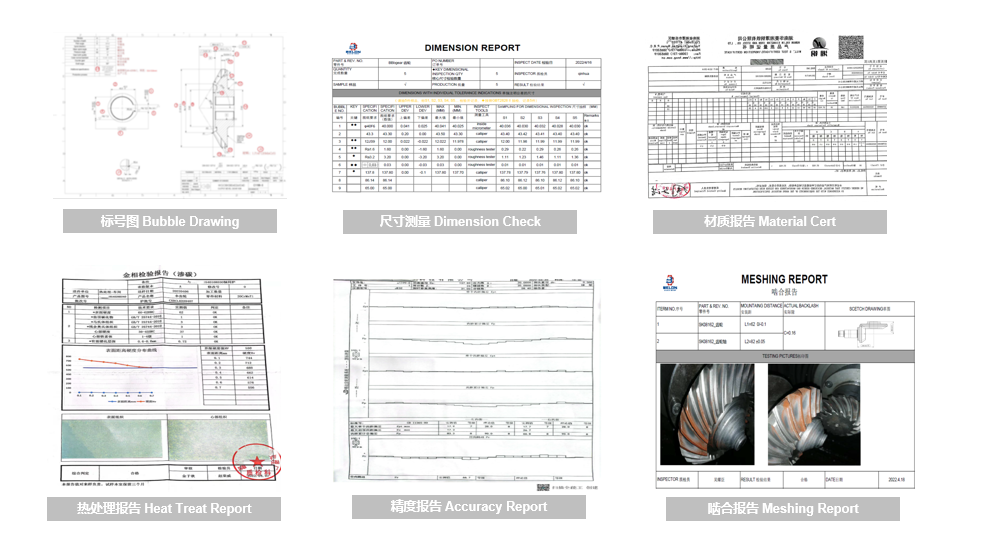

Hlobo luni lwemibiko ezonikezwa amakhasimende ngaphambi kokuthunyelwa ukuze kugaywe amagiya amakhulu e-spiral bevel ?

1) Umdwebo webhamuza

2) Umbiko wobukhulu

3) Isitifiketi sezinto ezibonakalayo

4) Umbiko wokuphatha ukushisa

5)Umbiko wokuhlolwa kwe-Ultrasonic (UT)

6)Umbiko wokuhlolwa kwe-Magnetic Particle (MT)

Umbiko wokuhlola we-Meshing