I-Gleasonamagiya e-bevel ajikelezayouhlobo olukhethekile lwegiya le-bevel elenzelwe ukudlulisa amandla phakathi kwemishayo ehlanganayo, ngokuvamile nge-engeli engama-degree angu-90. Okwenza uhlelo lwe-Gleason luhluke yindlela yalo ehlukile yokuma kwamazinyo nendlela yokukhiqiza, enikeza ukunyakaza okubushelelezi, amandla aphezulu e-torque, kanye nokusebenza okuthule. Lawa magiya asetshenziswa kabanzi ekudlulisweni kwezimoto, kwezimboni, kanye nasezindiza lapho ukuthembeka nokunemba kubalulekile khona.

Uhlelo lweGleason lwakhiwe ukuze luthuthuke uma kukhulunywa ngokuqondile nangokuqondile.amagiya e-bevel e-zerolngokufaka izinyo eligobile, elinomumo ojikelezayo. Lolu hlobo olujikelezayo lwenza kube lula ukuhlangana kancane kancane phakathi kwamazinyo, kunciphisa kakhulu umsindo nokudlidliza ngenkathi kuvumela isivinini esiphezulu sokujikeleza kanye nomthamo womthwalo. Umklamo uphinde uthuthukise isilinganiso sokuxhumana kanye namandla obuso, okuqinisekisa ukudluliselwa kwamandla okuphumelelayo ngaphansi kwemithwalo esindayo noma enamandla.

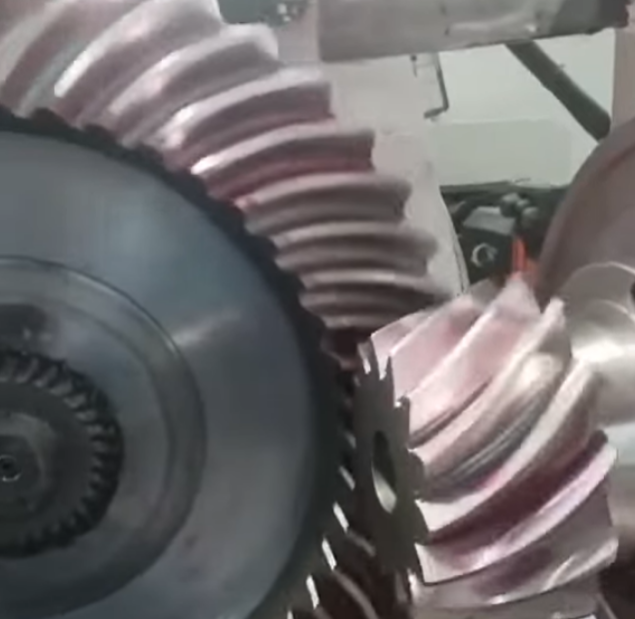

Ipheya ngalinye legiya le-Gleason spiral bevel liqukethe i-pinion kanye negiya lokuhlanganisa, elikhiqizwa nge-geometry ehambisanayo. Inqubo yokukhiqiza ikhethekile kakhulu. Iqala ngokubumba noma ukuphonswa ngokunemba kwezikhala zensimbi ye-alloy, njenge-18CrNiMo7-6, kulandelwe ukusika okuqinile, ukugoba, noma ukubumba ukuze kukhiqizwe ifomu legiya lokuqala. Izindlela ezithuthukisiwe ezifana nomshini we-axis 5, ukuskiya, kanye nokusika okuqinile ziqinisekisa ukunemba okuphezulu kanye nokuqeda okuphezulu kwendawo. Ngemva kokwelashwa kokushisa okufana ne-carburization (58–60 HRC), amagiya adlula ekugoqweni noma ekugayweni ukuze kufezwe i-meshing ephelele phakathi kwe-pinion negiya.

I-geometry yamagiya e-Gleason spiral bevel ichazwa yimingcele eminingana ebalulekile—i-angle ejikelezayo, i-angle yokucindezela, ibanga le-pitch cone, kanye nobubanzi bobuso. Lawa mapharamitha abalwa ngokunembile ukuqinisekisa amaphethini okuxhumana kwamazinyo afanele kanye nokusatshalaliswa komthwalo. Ngesikhathi sokuhlolwa kokugcina, amathuluzi anjengomshini wokulinganisa ohlanganisayo (CMM) kanye nokuhlaziywa kokuxhumana kwamazinyo (TCA) aqinisekisa ukuthi isethi yamagiya ihlangabezana nesigaba sokunemba esidingekayo se-DIN 6 noma i-ISO 1328-1.

Isebenza, i-Gleason spiralamagiya e-bevelanikeza ukusebenza kahle okuphezulu kanye nokusebenza okuzinzile ngisho nangaphansi kwezimo ezinzima. Amazinyo agobile ahlinzeka ngokuxhumana okuqhubekayo, kunciphisa ukugxila ekucindezelekeni kanye nokuguguleka. Lokhu kuwenza afaneleke kakhulu kuma-differentials ezimoto, ama-gearbox amaloli, imishini esindayo, izinhlelo zokuqhuba zasolwandle, kanye namathuluzi kagesi. Ngaphezu kwalokho, ikhono lokwenza ngokwezifiso i-geometry yamazinyo kanye nebanga lokufaka livumela onjiniyela ukuthi bathuthukise umklamo we-torque ethile, isivinini, kanye nemikhawulo yesikhala.

Igiya le-bevel elijikelezayo lohlobo lwe-Gleason — ithebula lokubala eliyisihluthulelo

| Into | Ifomula / Ukuvezwa | Okuguquguqukayo / Amanothi |

|---|---|---|

| Amapharamitha okufaka | (z_1,\ z_2,\ m_n,\ \alpha_n,\ \Sigma,\ b,\ T) | amazinyo e-pinion/igiya (z); imodyuli evamile (m_n); i-angle evamile yokucindezela (\alpha_n); i-angle yomgodi (\Sigma); ububanzi bobuso (b); i-torque edluliselwe (T). |

| Ububanzi bereferensi (isilinganiso) | (d_i = z_i , m_n) | i = 1 (pinion), 2 (igiya). Ububanzi obumaphakathi/bereferensi esigabeni esijwayelekile. |

| Ama-angles e-pitch (cone) | (\delta_1,\ \delta_2) kangangokuthi (\delta_1+\delta_2=\Sigma) kanye (\dfrac{\sin\delta_1}{d_1}=\dfrac{\sin\delta_2}{d_2}) | Xazulula ama-engeli ekhoni ahambisana nobukhulu bezinyo kanye ne-engeli yomgodi. |

| Ibanga lekhoni (ibanga le-pitch apex) | (R = \dfrac{d_1}{2\sin\delta_1} = \dfrac{d_2}{2\sin\delta_2}) | Ibanga elisuka ku-cone apex kuya ku-pitch circle lilinganiswa ku-generatrix. |

| Iphimbo eliyindilinga (elijwayelekile) | (p_n = \pi m_n) | Iphimbo eliqondile esigabeni esijwayelekile. |

| Imojuli eguquguqukayo (cishe) | (m_t = \dfrac{m_n}{\cos\beta_n}) | (\beta_n) = i-angle evamile yokujikeleza; ishintsha phakathi kwezingxenye ezijwayelekile neziphambeneyo njengoba kudingeka. |

| I-angle ejikelezayo (ubudlelwano obuphakathi/obunqamula) | (\tan\beta_t = \tan\beta_n \cos\delta_m) | (\delta_m) = i-angle ephakathi kwekhoni; sebenzisa ukuguqulwa phakathi kwama-angle ajwayelekile, aphambeneyo, kanye naphakathi ajikelezayo. |

| Isincomo sobubanzi bobuso | (b = k_b , m_n) | (k_b) ngokuvamile kukhethwa kusuka ku-8 kuya ku-20 kuye ngosayizi kanye nokusetshenziswa; bheka indlela yokuklama ukuze uthole inani eliqondile. |

| Isithasiselo (isilinganiso) | (a \cishe m_n) | Isilinganiselo esijwayelekile sokujula okugcwele kwesithasiselo; sebenzisa amathebula aqondile okulinganisa amazinyo ukuze uthole amanani aqondile. |

| Ububanzi obungaphandle (isihloko) | (d_{o,i} = d_i + 2a) | i = 1,2 |

| Ububanzi bempande | (d_{f,i} = d_i – 2h_f) | (h_f) = i-dedendum (kusukela kuzilinganiso zesistimu yegiya). |

| Ubukhulu bezinyo obuyindilinga (cishe) | (s \approx \dfrac{\pi m_n}{2}) | Ukuze uthole i-geometry ye-bevel sebenzisa ukujiya okulungisiwe okuvela ematafuleni amazinyo ukuze uthole ukunemba. |

| Amandla e-tangential embuthanweni we-pitch | (F_t = \dfrac{2T}{d_p}) | (T) = i-torque; (d_p) = ububanzi bephimbo (sebenzisa amayunithi ahambisanayo). |

| Ukucindezeleka okugobile (okwenziwe lula) | (\sigma_b = \dfrac{F_t \cdot K_O \cdot K_V}{b \cdot m_n \cdot Y}) | (K_O) = isici sokulayisha ngokweqile, (K_V) = isici esiguquguqukayo, (Y) = isici sefomu (i-geometry egobayo). Sebenzisa i-equation ephelele yokugoba ye-AGMA/ISO yokuklama. |

| Ukucindezeleka kokuthintana (uhlobo lwe-Hertz, olulula) | (\sigma_H = C_H \sqrt{\dfrac{F_t}{d_p , b} \cdot \dfrac{1}{\frac{1-\nu_1^2}{E_1}+\frac{1-\nu_2^2}{E_2}}}) | (C_H) i-geometry constant, (E_i,\nu_i) i-elastic moduli yezinto ezibonakalayo kanye ne-Poisson ratios. Sebenzisa izilinganiso ezigcwele zokuthintana nokucindezeleka ukuze uqinisekise. |

| Isilinganiso sokuxhumana (okujwayelekile) | (\varepsilon = \dfrac{\text{arc of action}}{\text{base pitch}}) | Kumagiya e-bevel, bala usebenzisa i-pitch cone geometry kanye ne-spiral angle; ngokuvamile kuhlolwa ngamatafula noma isofthiwe yokuklama amagiya. |

| Inani lamazinyo elingokoqobo | (z_v \approx \dfrac{d}{m_t}) | Iwusizo ekuhlolweni kokuxhumana/ukunciphisa; (m_t) = imodyuli enqamulayo. |

| Ukuhlolwa kwamazinyo amancane / ukusika okungaphansi | Sebenzisa isimo samazinyo esincane ngokusekelwe ekhoneni elijikelezayo, ekhoneni lokucindezela kanye nobukhulu bamazinyo | Uma u-(z) engaphansi kobuncane, kudingeka amathuluzi angaphansi noma akhethekile. |

| Izilungiselelo zomshini/zokusika (isinyathelo sokuklama) | Nquma ama-engeli ekhanda lokusika, ukujikeleza kwe-cradle kanye nokukhomba kusuka ku-geometry yesistimu yegiya | Lezi zilungiselelo zithathwe ku-geometry yegiya kanye nohlelo lokusika; landela inqubo yomshini/yamathuluzi. |

Ubuchwepheshe besimanje bokukhiqiza, njengemishini yokusika nokugaya amagiya e-CNC bevel, buqinisekisa ikhwalithi ehambisanayo kanye nokushintshana. Ngokuhlanganisa umklamo osizwa yikhompyutha (i-CAD) kanye nokulingisa, abakhiqizi bangenza ubunjiniyela obubuyela emuva kanye nokuhlolwa okubonakalayo ngaphambi kokukhiqiza kwangempela. Lokhu kunciphisa isikhathi sokukhokha kanye nezindleko ngenkathi kuthuthukiswa ukunemba nokuthembeka.

Ngamafuphi, amagiya e-Gleason spiral bevel amelela inhlanganisela ephelele ye-geometry ethuthukisiwe, amandla ezinto ezibonakalayo, kanye nokunemba kokukhiqiza. Amandla awo okuletha ukudluliselwa kwamandla okubushelelezi, okusebenzayo, nokuhlala isikhathi eside kuwenze aba yingxenye ebalulekile ezinhlelweni zokushayela zesimanje. Kungakhathaliseki ukuthi asetshenziswa emikhakheni yezimoto, yezimboni, noma yezindiza, la magiya ayaqhubeka nokuchaza ubuhle bokuhamba nokusebenza kahle kwemishini.

Isikhathi sokuthunyelwe: Okthoba-24-2025