Amagiya okusansimbi kafulawa

I-powder metallurgy iyindlela yokukhiqiza ehilela ukuhlanganisa izimpushana zensimbi ngaphansi komfutho ophezulu bese uzishisa emazingeni okushisa aphezulu ukuze zakhe izingxenye eziqinile.

Insimbi eyimpuphuamagiyazisetshenziswa kabanzi ezimbonini ezahlukahlukene njengezimoto, imishini yezimboni kanye nezinhlelo zokusebenza zokudlulisa amandla.

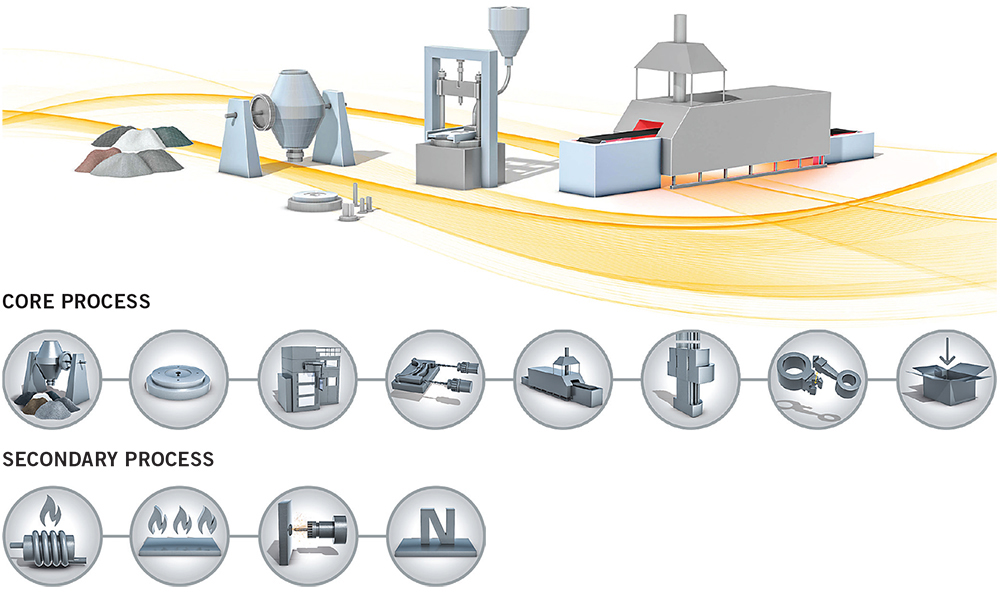

Inqubo eyinhloko yokusansimbi yempuphu ihlanganisa ukuxuba i-powder, ukusebenzisa amathuluzi, ukucindezela i-powder, ukugaya okuluhlaza, ukucwilisa, ukulinganisa, ukupakisha kanye nokuhlolwa kokugcina. Imisebenzi yesibili ihlanganisa ukuqinisa i-induction, ukugaya ukushisa kanye nokufaka i-nitriding.

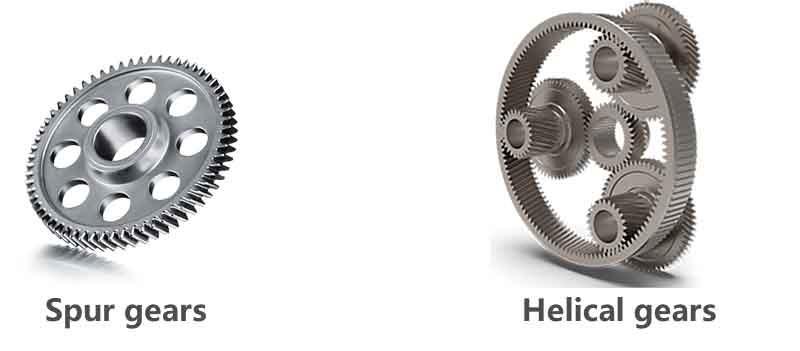

Amagiya ensimbi ewuphu, njengamagiya akhiqizwa ezinye izindlela zokukhiqiza, angacutshungulwa abe yizimo zamazinyo ezahlukahlukene ngokuya ngezidingo. Ezinye zezimo zamazinyo ezivamile zamagiya ensimbi ewuphu zifaka:amagiya okucindezela, amagiya ajikelezayo.

Izinto zensimbi eziwuphawuda:

Lapho ukhetha izinto zokwakha amagiya e-powder metallurgy, kunezinto eziningana okudingeka zicatshangelwe: izakhiwo zemishini, ubuningi, ukuthambisa kanye nokuguguleka, izindleko

Izinkambu zohlelo lokusebenza:

Amagiya ensimbi ewuphawuda asetshenziswa ezinhlotsheni eziningi zezinhlelo zezimoto, okuhlanganisa:

1. I-Gearbox: Amagiya ensimbi ewuphawuda asetshenziswa kabanzi kuma-gearbox azenzakalelayo nawasebenzisa ngesandla ukuze anikeze ukudluliselwa kwamandla okuthembekile nokuphumelelayo phakathi kwenjini namasondo. Amandla awo aphezulu kanye nokumelana nokuguguleka kuqinisekisa ukuguquguquka okubushelelezi, i-gear mesh ethuthukisiwe kanye nokuphila isikhathi eside kokudluliselwa.

2. Izitimela Zamandla Kagesi: Njengemboni yezimotoukushintshaEzimotweni zikagesi (ama-EV), amagiya ensimbi ewuphuphu adlala indima ebalulekile ezinjinini zikagesi. Lawa magiya asetshenziswa kuma-drive kagesi, ama-gearbox kanye nama-differentials ukuze anikeze i-torque edingekayo kanye nesivinini esidingekayo ukuze kusebenze kahle kakhulu i-EV.

3. Uhlelo lokuqondisa: Uhlelo lokuqondisa lusebenzisa amagiya ensimbi anombala ophuzi ukudlulisa amandla kusuka esiteringini kuya emasondweni. Ukuqina kwawo, ukunemba kwawo kanye nokusebenza kwawo buthule kunegalelo ekulawuleni ukuqondisa okusabelayo nokunembile.

Isikhathi sokuthunyelwe: Agasti-28-2023