Izinhlelo zegiya zidlala indima ebalulekile kumadivayisi ahlukahlukene emishini, ziqinisekisa ukudluliswa kwamandla okushelelayo nokuphumelelayo. Kodwa-ke, ukusebenza kwezinhlelo zegiya kuncike kakhulu ekunembenii-gear meshingNgisho nokuphambuka okuncane kungaholela ekungasebenzi kahle, ekugugeni okukhulu, ngisho nasekuhlulekeni okubi kakhulu. Kulesi sihloko, sizohlola izici ezithinta ukunemba kwe-gear mesh futhi sihlole ukubaluleka kwazo ekuqinisekiseni ukusebenza kahle kwesistimu yegiya.

Iphrofayili Yezinyo Legiya:

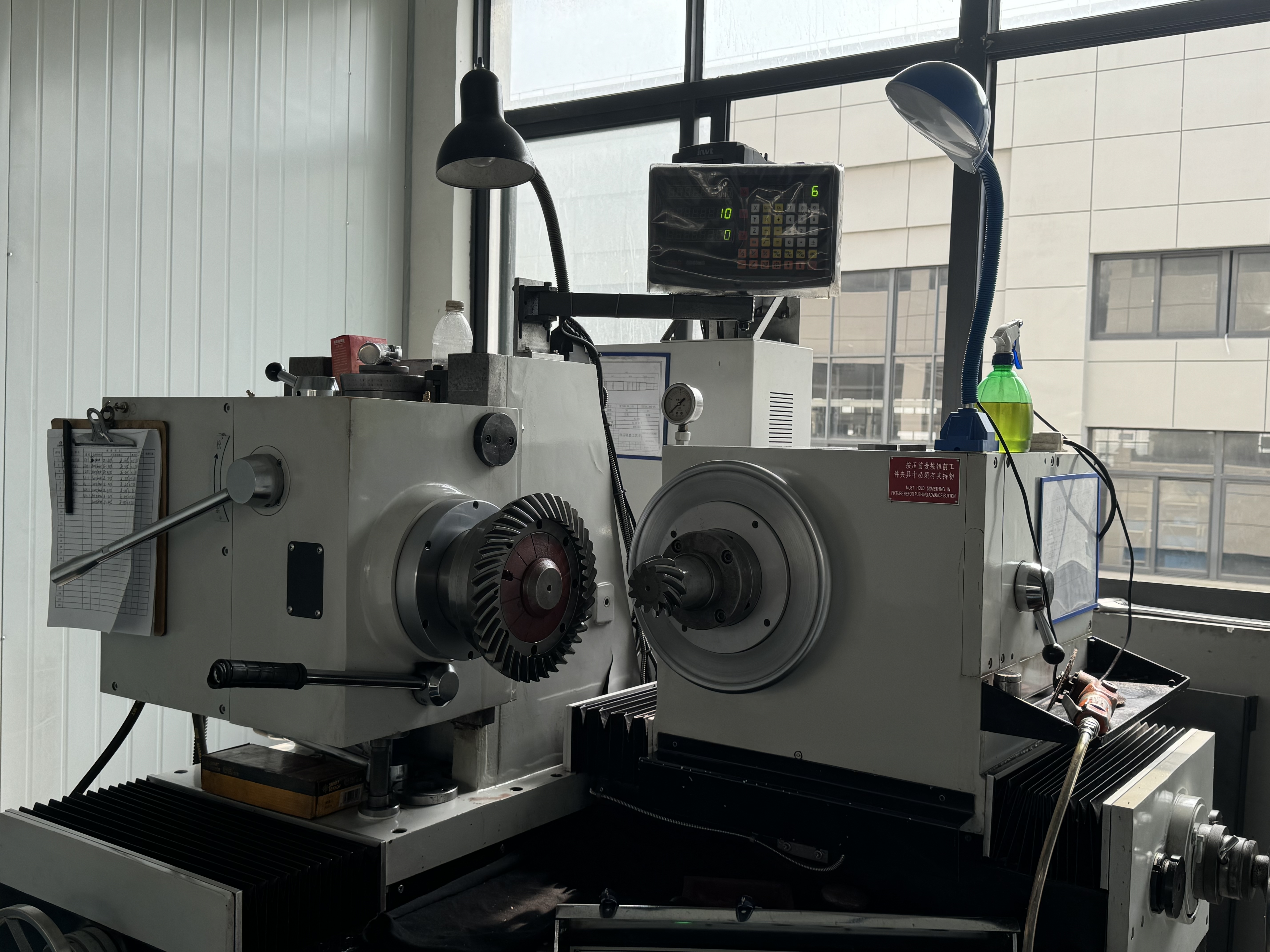

Iphrofayili yamazinyo egiya mhlawumbe iyisici esiyisisekelo esithonya ukunemba kwe-gear mesh. Amazinyo kumele akhiwe ngendlela efanele ukuqinisekisa ukuzibandakanya okufanele kanye nokunciphisa ukujikijelana. Noma yikuphi ukuphambuka kuphrofayili yamazinyo efanele kungaholela ekuthwaleni okungalingani, umsindo owandisiwe, kanye nokusebenza kahle okuncishisiwe. Amasu okukhiqiza esimanje anjengomshini we-CNC athuthukise kakhulu ikhono lokukhiqiza amaphrofayili anembile amazinyo egiya.

Ukubekezelelana Kokukhiqiza:

Izinqubo zokukhiqiza ngokungenakugwenywa ziletha ukubekezelelana, okungathinta ukunemba kwe-gear mesh. Ukwehluka ngobukhulu, ukuqeda kobuso, kanye nezakhiwo zezinto kungathinta indlela amagiya asebenzisana ngayo ngesikhathi sokufaka i-mesh. Ukubekezelelana okuqinile kanye nezinyathelo zokulawula ikhwalithi ngesikhathi sokukhiqiza kubalulekile ukuqinisekisa ukusebenza kahle kwegiya.

Ukuqondanisa Nokuhlanganisa:

Ukuqondanisa okufanele kanye nokuhlanganiswa kweigiyaizinhlelo zibalulekile ekufinyeleleni ukunemba okuhle kakhulu kwe-mesh. Ukungalungi kahle kwemiphini, isikhala esingalungile phakathi kwamagiya, noma ukulayisha kusengaphambili okungafanele amabhere kungaholela ekulayisheni okungalingani kanye nokuguguleka kwangaphambi kwesikhathi. Ukunaka ngokucophelela izinqubo zokuhlanganisa, okuhlanganisa ukusetshenziswa kwamathuluzi okuqondisa kanye nemininingwane ye-torque, kuyadingeka ukunciphisa lezi zinkinga.

Ukugcotshwa:

Ukugcotshwa okusebenzayo kubalulekile ekunciphiseni ukungqubuzana kanye nokuguguleka phakathi kwamazinyo egiya. Ukugcotshwa okunganele noma okungafanele kungabangela ukungqubuzana okwandisiwe, ukushisa ngokweqile, kanye nokuguguleka okusheshayo. Ukukhethwa kokugcotshwa okulungile, kanye nokugcinwa njalo kanye nokuqapha amazinga okugcotshwa, kubalulekile ekugcineni ukunemba kwe-gear mesh ngokuhamba kwesikhathi.

Izimo Zokusebenza:

Indawo yokusebenza ingathinta nokunemba kwe-gear mesh. Izici ezifana nokushintshashintsha kwezinga lokushisa, imithwalo yokushaqeka, kanye nokungcola kungathinta ukusebenza kwamagiya.igiyaizinhlelo ezinezivikelo ezifanele kanye nokucabangela izimo zokusebenza ezihlosiwe kungasiza ekunciphiseni le miphumela nokuqinisekisa ukusebenza okuthembekile.

Ukuguguleka Nokuwohloka:

Ngokuhamba kwesikhathi, amagiya angase aguge futhi awe, okuthinta ukunemba kwawo kwe-mesh. Izinhlayiya ezigugulekayo, ukugcotshwa okunganele, noma imithwalo eminingi kakhulu kungasheshisa ukuguguleka futhi kuholele ekushintsheni kwejiyometri yamagiya. Ukuhlolwa nokugcinwa njalo kubalulekile ekutholeni nasekuxazululeni izinkinga zokuguguleka ngaphambi kokuba ziphazamise ukusebenza kwegiya.

Ukufeza nokulondolozaigiyaUkunemba kwe-mesh kubalulekile ekuqinisekiseni ukusebenza okuthembekile nokuphumelelayo kwezinhlelo zemishini. Ngokuqonda izici ezithonya ukunemba kwe-mesh yegiya kanye nokusebenzisa izinyathelo ezifanele ngesikhathi sokuklama, ukukhiqiza, ukuhlanganisa, kanye nokusebenza, onjiniyela bangenza ngcono ukusebenza kwegiya futhi bandise isikhathi sokuphila kwezinhlelo zegiya. Intuthuko eqhubekayo kubuchwepheshe bokukhiqiza nezinto zokwakha, kanye nemikhuba yokulawula ikhwalithi eqinile, izoqhubeka nokuthuthukisa ukunemba kwe-mesh yegiya kanye nokushayela ukusungula izinto ezintsha kubunjiniyela bemishini.

Isikhathi sokuthunyelwe: Meyi-07-2024