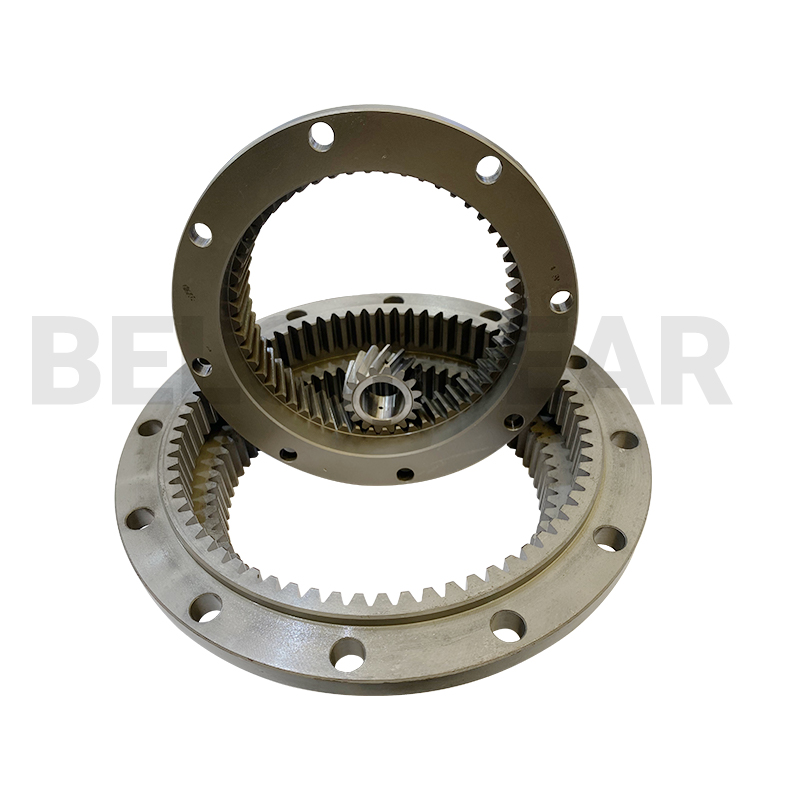

Amagiya angaphakathiuhlobo lwegiya lapho amazinyo esikwa khona ngaphakathi kwesilinda noma ikhoni, ngokungafani namagiya angaphandle lapho amazinyo engaphandle. Ahlanganisa amagiya angaphandle, futhi ukwakheka kwawo kuwenza akwazi ukudlulisa ukunyakaza namandla ezinhlelweni ezahlukene zemishini.

Kunezinhlelo zokusebenza eziningana zamagiya angaphakathi:

- Izinhlelo Zegiya Leplanethi: Amagiya angaphakathi avame ukusetshenziswa ezinhlelweni zegiya leplanethi, lapho ehlangana khona negiya lelanga kanye namagiya eplanethi. Leli lungiselelo livumela izitimela zegiya ezihlangene neziguquguqukayo, ezivame ukusetshenziswa ekudlulisweni kwezimoto kanye nemishini yezimboni.

- Ukudluliselwa Kwamandla: Amagiya angaphakathi angasetshenziswa ukudlulisa amandla phakathi kwemishafu ehambisanayo noma ehlanganayo. Avame ukusetshenziswa ezimweni lapho imikhawulo yesikhala noma izidingo ezithile ze-torque zidinga ukusetshenziswa kwawo.

- Ukunciphisa Isivinini noma Ukwenyuka: Amagiya angaphakathiingasetshenziswa ukwandisa noma ukunciphisa isivinini sokujikeleza kuye ngokucushwa kwayo kanye nokuhlanganiswa kwayo ngamagiya angaphandle.

- Ukulawula Ukunyakaza: Kumarobhothi kanye nokuzenzakalelayo, amagiya angaphakathi asetshenziselwa ukulawula ukunyakaza okunembile, okuqinisekisa ukunyakaza okubushelelezi nokunembile ezingalweni zamarobhothi, imishini ye-CNC, kanye nezinye izinhlelo ezizenzakalelayo.

- Izindlela Zokuhluka: Amagiya angaphakathi angatholakala nasezindleleni ezihlukile, njengalezo ezisetshenziswa ezitimeleni zokushayela izimoto, ukuze kusatshalaliswe amandla kanye ne-torque phakathi kwamasondo ngenkathi ewavumela ukuthi ajikeleze ngesivinini esihlukile.

- In amarobhothi kanye nokuzenzakalela, amagiya angaphakathi asetshenziswa kabanzi ukufeza ukunyakaza okunembile ngaphakathi kwezikhala ezilinganiselwe. Izingalo zamarobhothi, isibonelo, zivame ukusebenzisa amagiya angaphakathi kuma-actuator azo ukuze zinikeze indawo enembile ngokunciphisa ukujikijela, okuvumela ukunyakaza okubushelelezi nokulawulwa kakhudlwana. Uhlobo oluncane lwamagiya angaphakathi lusiza onjiniyela ukuhlanganisa izinhlelo zamagiya eziyinkimbinkimbi ezihlanganisweni ezincane, okuvumela amarobhothi ukuthi alondoloze izinga eliphezulu lokushesha nokusebenza kahle ngaphandle kokulahlekelwa amandla noma ukulawula.

- Amagiya angaphakathi futhi kuyisinqumo esidumile kuizimoto zikagesi (ama-EV), ikakhulukazi kuma-gearbox aklanyelwe ukuphatha isivinini esikhulu sokujikeleza. Ama-motor e-EV avame ukusebenza ngesivinini esiphezulu kakhulu kunezinjini zokushisa zangaphakathi, ngakho-ke amagiya angaphakathi, ahlanganiswe nezinhlelo zamagiya eplanethi, abalulekile ekunciphiseni isivinini ngenkathi kwandiswa i-torque. Lokhu kusethwa kuthuthukisa ukusebenza kahle kwamandla, okuholela ekulethweni kwamandla okushelelayo kanye nokuphila kwebhethri okweluliwe.

- In imishini yokunyathelisafuthiimishini yendwangu, lapho ukunemba okuphezulu kubalulekile khona, amagiya angaphakathi asetshenziswa ezinhlelweni ezidinga ukugcina ukujikeleza okuvumelanisiwe kanye nesivinini. Ukusethwa kwamagiya angaphakathi kusiza ukufeza ukuhambisana nokunemba kokunyakaza, okufaka isandla ekhwalithini yomkhiqizo wokugcina, kungaba izinto eziphrintiwe noma izindwangu. Isimo sazo esincane kanye namakhono okwabelana ngemithwalo asebenzayo kwenza le mishini isebenze ngesivinini esiphezulu ngaphandle kokufaka engcupheni yokungahambisani kahle noma ukuguguleka ngokweqile.

Ngaphezu kwalokho,imishini yezokwelaphanjengamarobhothi okuhlinzwa kanye nezinhlelo zokuthwebula izithombe zivame ukusebenzisa amagiya angaphakathi kuma-actuator azo ukuze kuhambisane kahle futhi kulawulwa ngaphakathi kwezikhala ezincane. Amagiya angaphakathi asiza ekugcineni ukunemba nokuzinza, okubalulekile ekusebenzeni okubucayi, ekuxilongweni nasekuphepheni kwesiguli.

Ukwakheka nokukhiqizwa kwamagiya angaphakathi kungaba yinkimbinkimbi kakhulu kunegiya langaphandle ngenxa yobunzima bokufinyelela ingaphakathi legiya ngesikhathi somshini. Kodwa-ke, anikeza izinzuzo kwezinye izinhlelo zokusebenza, njengokubuncane, ukwanda komthamo wokudlulisa i-torque, kanye nokusebenza okubushelelezi.

Isikhathi sokuthunyelwe: Ephreli-30-2024