Esikhathini sobuchwepheshe obuxhumene, siyakuqonda ukubaluleka kokuxhumana nokusebenza okuhlakaniphile.Amasistimu ethu egiya aklanywe ngokuhambisana engqondweni, ahlanganiswe ngaphandle komthungo namasistimu okuqapha nokulawula kwedijithali.Lokhu kuxhumana akugcini nje ngokuthuthukisa ukusetshenziswa kalula kodwa futhi kusiza ukunakekelwa okubikezelwayo, ukunciphisa isikhathi sokuphumula futhi kuthuthukise ukusebenza kahle kohlelo lonke.

Njengengxenye yokuzibophezela kwethu ekulawuleni ikhwalithi, sisebenzisa izinqubo zokuhlola eziqinile kuyo yonke inqubo yokukhiqiza.Lokhu kuqinisekisa ukuthi isistimu yamagiya ngayinye eshiya izinsiza zethu inamathela emazingeni aphezulu kakhulu, okunikela edumeni lokwethembeka nokungaguquguquki.

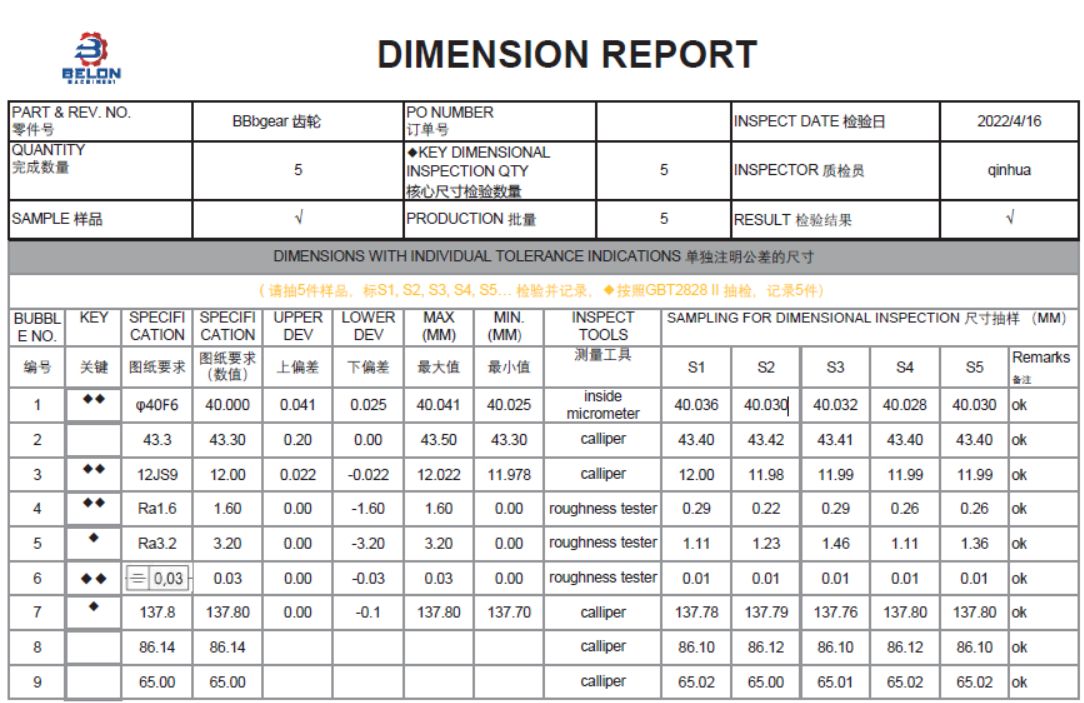

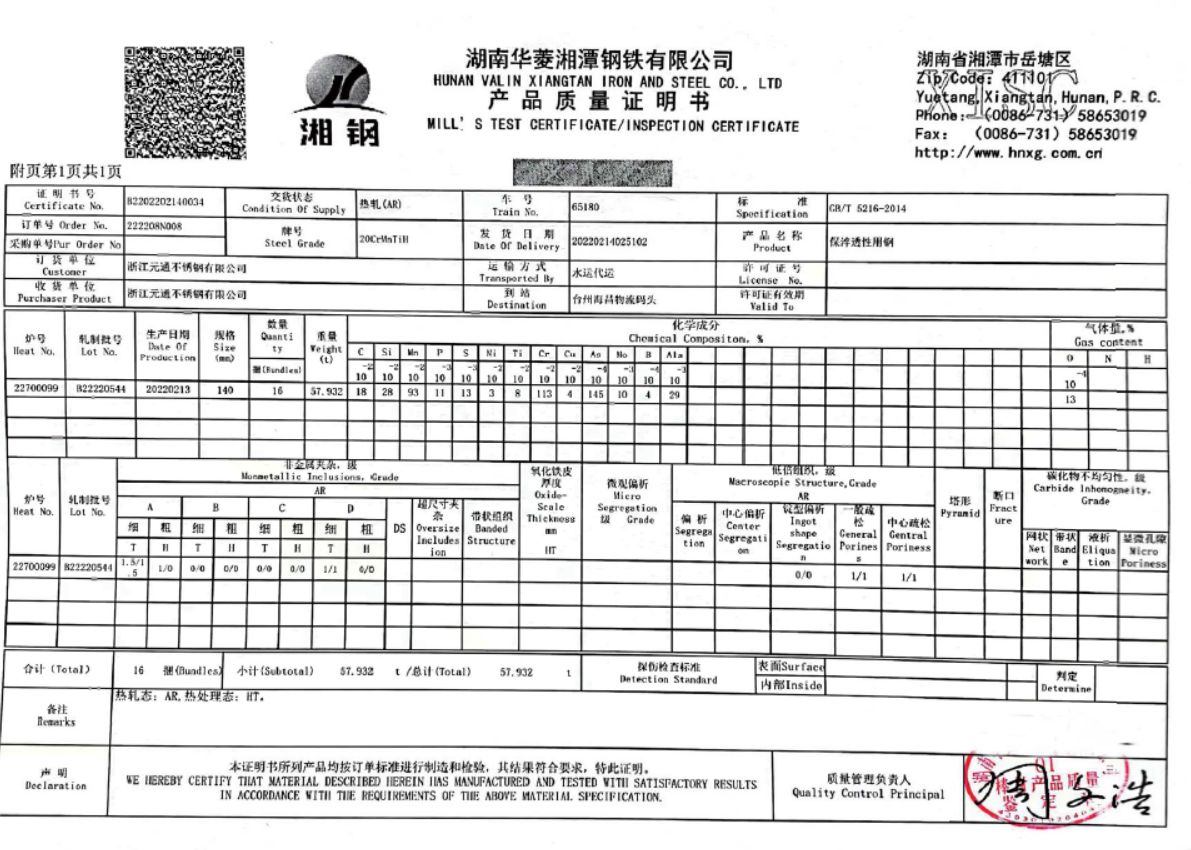

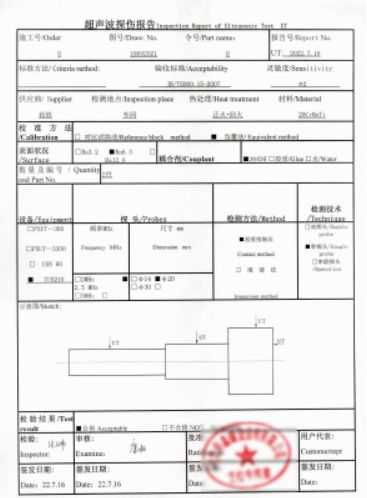

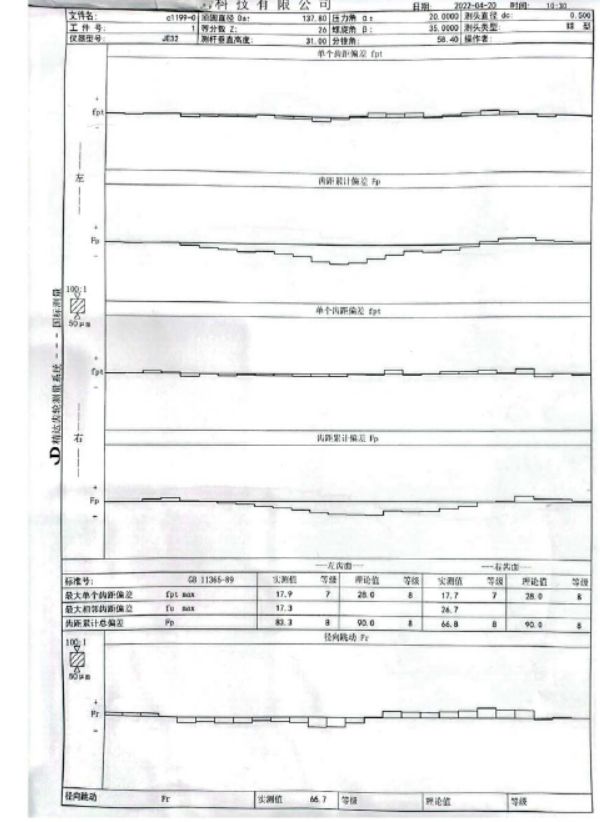

Hlobo luni lwemibiko ezonikezwa amakhasimende ngaphambi kokuthunyelwa ukuze kugaywe amagiya amakhulu e-spiral bevel ?

1) Umdwebo webhamuza

2) Umbiko wobukhulu

3) Isitifiketi sezinto ezibonakalayo

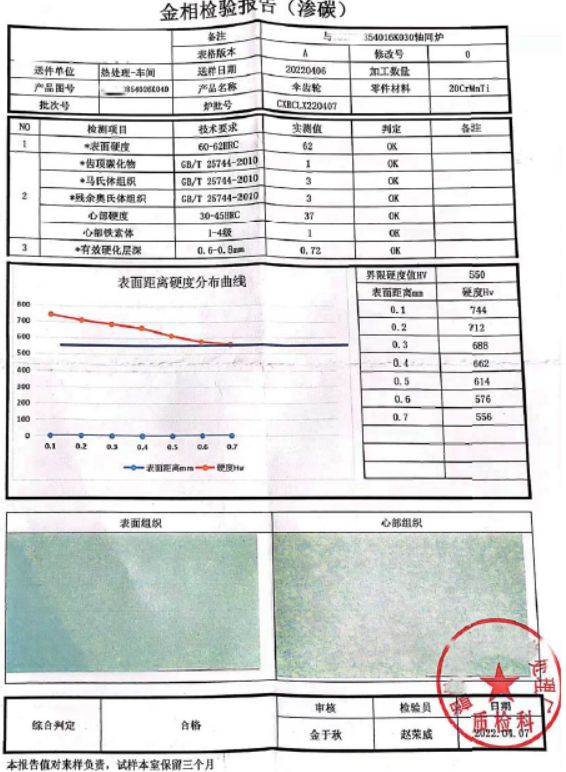

4) Umbiko wokuphatha ukushisa

5) Umbiko wokuhlolwa kwe-Ultrasonic (UT)

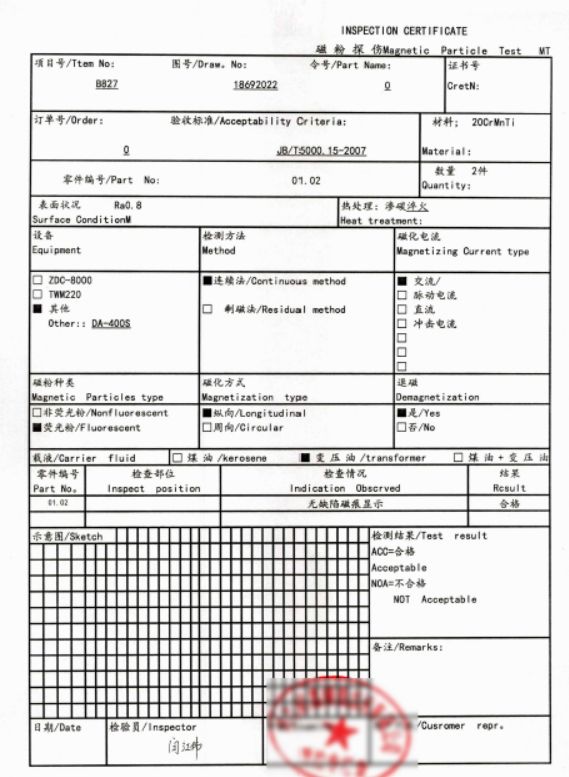

6) Umbiko wokuhlolwa kwe-Magnetic Particle (MT)

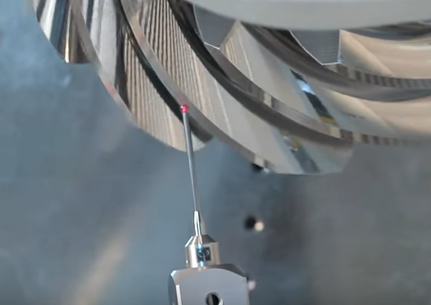

Umbiko wokuhlola we-Meshing

Sixoxa indawo engamamitha-skwele angu-200000, futhi efakwe kusengaphambili ukukhiqiza kanye nemishini yokuhlola ukuhlangabezana nesidingo samakhasimende.Sethule usayizi omkhulu kunayo yonke, isikhungo sokuqala semishini sase-China esiqondene ngqo negiya i-Gleason FT16000 selokhu kwaba nokubambisana phakathi kwe-Gleason ne-Holler.

→ Noma Yimaphi Amamojula

→ Noma yiziphi Izinombolo Zamazinyo

→ Ukunemba okuphezulu kwe-DIN5

→ Ukusebenza kahle okuphezulu, ukunemba okuphezulu

Ukuletha ukukhiqiza kwephupho, ukuguquguquka kanye nomnotho weqoqo elincane.

impahla eluhlaza

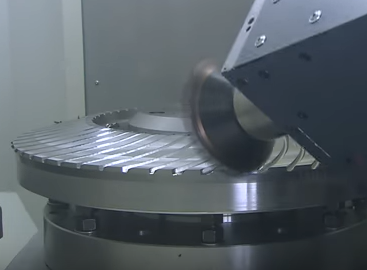

ukusika rough

ukuphenduka

ukuphefumula nokuphefumula

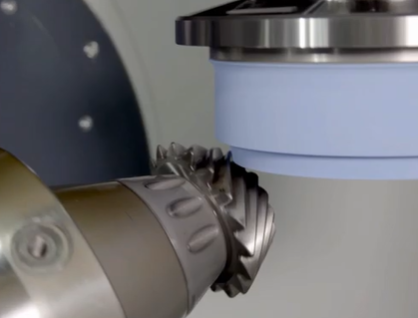

ukugaya amagiya

Ukuphatha ukushisa

ukugaya amagiya

ukuhlola