Izingxenye eziningi zeamagiya amasha okunciphisa amandlafuthiamagiya ezimotoIphrojekthi idinga ukuchama ngemva kokugaya igiya, okuzolimaza ikhwalithi yobuso bezinyo, futhi kuthinte nokusebenza kwe-NVH kohlelo. Leli phepha lifunda ubulukhuni bobuso bezinyo bezimo ezahlukene zenqubo yokuchama kanye nezingxenye ezahlukene ngaphambi nangemva kochama. Imiphumela ikhombisa ukuthi ukuchama ngemva kochama kuzokwandisa ubulukhuni bobuso bezinyo, obuthintwa izici zezingxenye, imingcele yenqubo yokuchama ngemva kochama kanye nezinye izici; Ngaphansi kwezimo zenqubo yokukhiqiza ibhetshi ezikhona, ubulukhuni obukhulu bobuso bezinyo ngemva kochama ngemva kochama buyizikhathi ezingu-3.1 kunangaphambi kochama ngemva kochama. Kuxoxwa ngethonya lobulukhuni bobuso bezinyo ekusebenzeni kwe-NVH, futhi kuphakanyiswa izinyathelo zokuthuthukisa ubulukhuni ngemva kochama ngemva kochama ngemva kochama.

Ngaphansi kwesizinda esingenhla, leli phepha lixoxa ngezici ezintathu ezilandelayo:

Ithonya lemigomo yenqubo yokuchama ngomjovo ekuqineni kobuso bezinyo;

Izinga lokukhulisa lokuchama kwesibhamu ebulukhuni bobuso bezinyo ngaphansi kwezimo zenqubo yokukhiqiza inqwaba ekhona;

Umthelela wokwanda kokuklwebheka kwezinyo ekusebenzeni kwe-NVH kanye nezindlela zokuthuthukisa ukuklwebheka ngemva kokuchama ngomjovo.

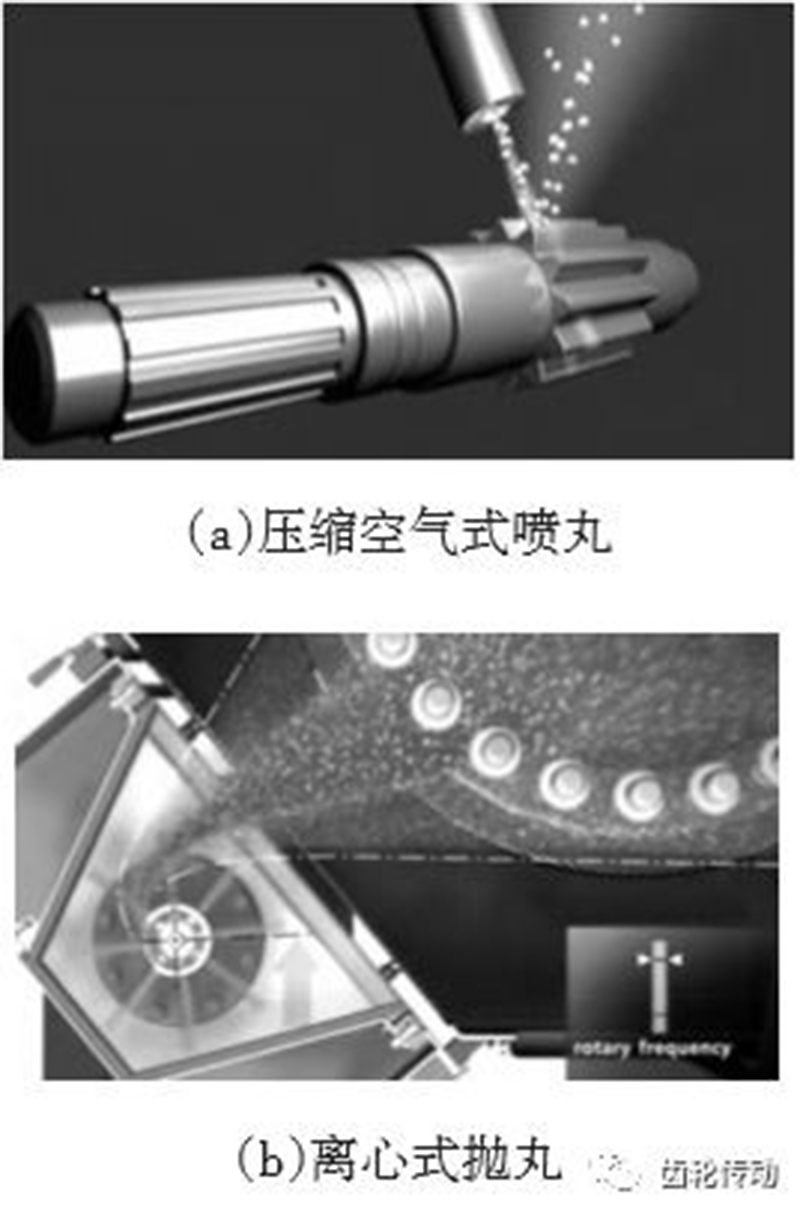

Ukuchama ngokudubula kubhekisela enkambisweni lapho iziqhumane eziningi ezincane ezinobunzima obukhulu kanye nokunyakaza ngesivinini esikhulu zishaya khona ubuso bezingxenye. Ngaphansi komthelela wesivinini esikhulu se-projectile, ubuso bengxenye buzokhiqiza imigodi futhi kuzokwenzeka ukuguquka kwepulasitiki. Izinhlangano ezizungeze imigodi zizomelana nalokhu kuguquka futhi zikhiqize ukucindezeleka okusele kokucindezela. Ukugqagqana kwemigodi eminingi kuzokwakha ungqimba lokucindezeleka olusele olufanayo ebusweni bengxenye, ngaleyo ndlela kuthuthukiswe amandla okukhathala kwengxenye. Ngokwendlela yokuthola isivinini esikhulu ngesibhamu, ukuchama ngokudubula ngokuvamile kuhlukaniswe ngokuchama ngokudubula komoya okucindezelwe kanye nokuchama ngokudubula kwe-centrifugal, njengoba kuboniswe kuMfanekiso 1.

Ukuchama komoya ocindezelwe kuthatha umoya ocindezelwe njengamandla okufafaza isibhamu esivela esibhamuni; Ukuchama kokudubula kwe-centrifugal kusebenzisa injini ukushayela i-impeller ukuthi ijikeleze ngesivinini esikhulu ukuze iphonse isibhamu. Amapharamitha enqubo ebalulekile yokuchama kokudubula afaka amandla okugcwala, ukumbozwa kanye nezakhiwo eziphakathi zokuchama kokudubula (izinto ezibonakalayo, usayizi, ukuma, ubulukhuni). Amandla okugcwala ayipharamitha yokuchaza amandla okuchama kokudubula, okuvezwa ukuphakama kwe-arc (okungukuthi izinga lokugoba kwengxenye yokuhlola ye-Almen ngemva kokuchama kokudubula); Izinga lokumboza libhekisela esilinganisweni sendawo embozwe umgodi ngemva kokuchama kokudubula endaweni iyonke yendawo echamayo; Imidiya yokuchama yokudubula evame ukusetshenziswa ifaka i-shot yensimbi yokusika, i-shot yensimbi ephonswe, i-ceramic shot, i-glass shot, njll. Usayizi, ukuma kanye nobunzima bemidiya yokuchama yokudubula kungamamaki ahlukene. Izidingo zenqubo ezijwayelekile zezingxenye zomgodi wegiya lokudlulisa ziboniswe kuThebula 1.

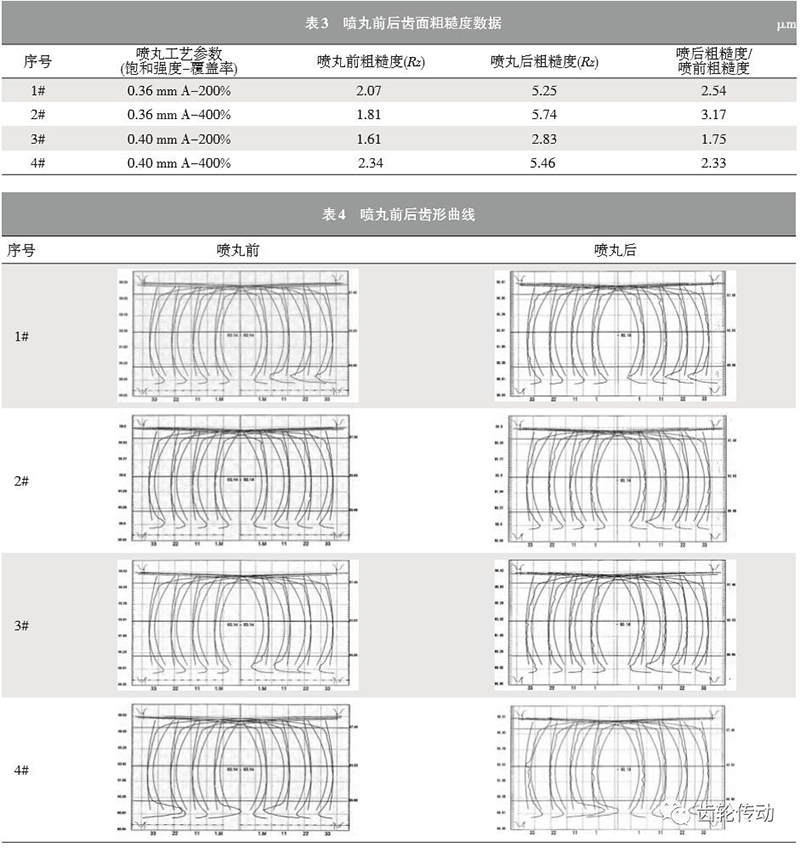

Ingxenye yokuhlola iyigiya eliphakathi nendawo elingu-1/6 lephrojekthi ye-hybrid. Isakhiwo segiya siboniswe kuMfanekiso 2. Ngemva kokugaya, isakhiwo esincane sobuso bezinyo siseBangeni 2, ubulukhuni bobuso bungu-710HV30, kanti ukujula kwengqimba yokuqinisa okusebenzayo kungu-0.65mm, konke kungaphansi kwezidingo zobuchwepheshe. Ubulukhuni bobuso bezinyo ngaphambi kokukhipha isibhamu buboniswe kuThebula 3, kanti ukunemba kwephrofayili yezinyo kuboniswe kuThebula 4. Kungabonakala ukuthi ubulukhuni bobuso bezinyo ngaphambi kokukhipha isibhamu bulungile, futhi ijika lephrofayili yezinyo libushelelezi.

Uhlelo lokuhlola kanye nemingcele yokuhlola

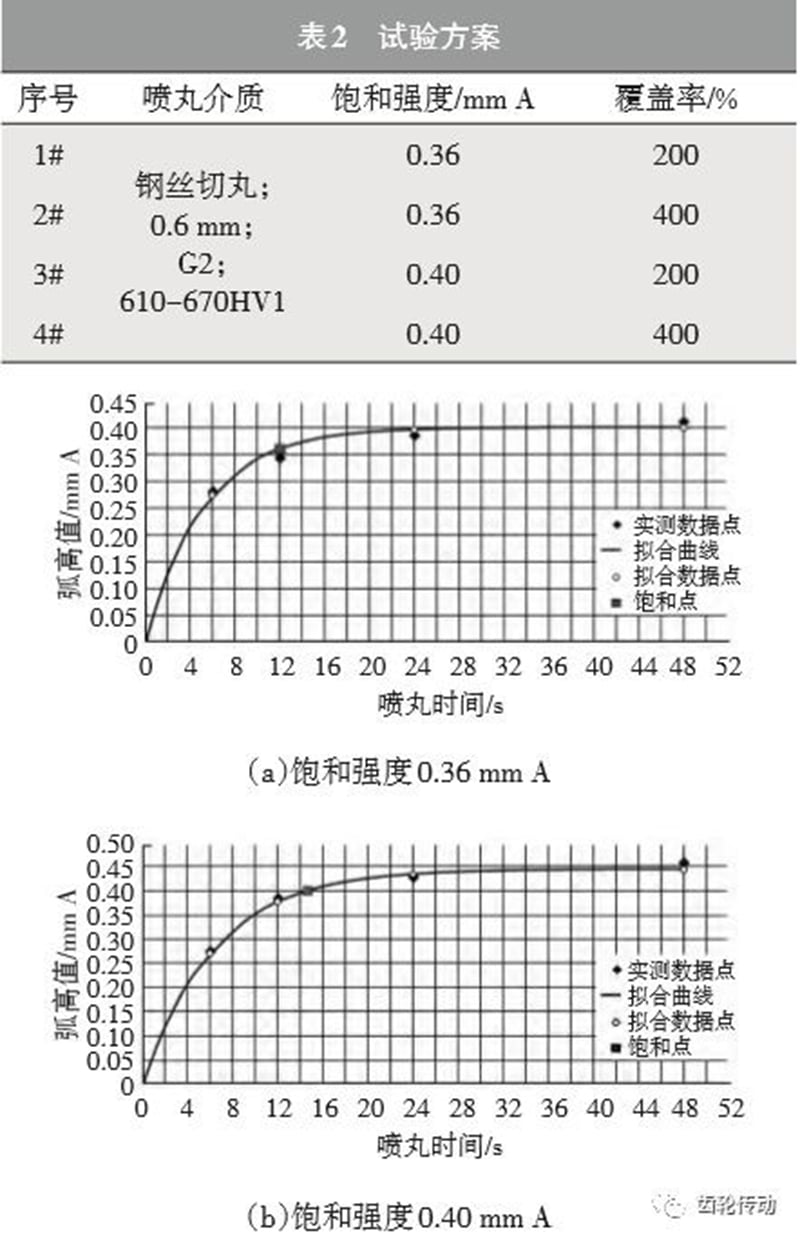

Umshini wokuchama ocindezelwe womoya osetshenziswa esivivinyweni. Ngenxa yezimo zokuhlola, akunakwenzeka ukuqinisekisa umthelela wezakhiwo eziphakathi zokuchama ngokudubula (izinto, usayizi, ubulukhuni). Ngakho-ke, izakhiwo zendawo yokuchama ngokudubula zihlala njalo esivivinyweni. Umthelela wamandla okugcwala kanye nokumbozwa kobulukhuni bobuso bezinyo ngemva kokuchama ngokudubula kuphela oqinisekiswayo. Bheka Ithebula 2 ukuze uthole uhlelo lokuhlola. Inqubo ethile yokunquma yamapharamitha okuhlola imi kanje: dweba ijika lokugcwala (Isithombe 3) ngokusebenzisa isivivinyo sekhuphoni se-Almen ukuze uthole iphuzu lokugcwala, ukuze uvale umfutho womoya ocindezelwe, ukugeleza kwesibhamu sensimbi, isivinini sokuhamba kwe-nozzle, ibanga le-nozzle kusuka ezingxenyeni kanye neminye imingcele yemishini.

umphumela wokuhlolwa

Idatha yobulukhuni bobuso bezinyo ngemva kokuchama ngokudubula iboniswe kuThebula 3, kanti ukunemba kwephrofayili yezinyo kuboniswe kuThebula 4. Kungabonakala ukuthi ngaphansi kwezimo zokuchama ngokudubula ezine, ubulukhuni bobuso bezinyo buyanda futhi ijika lephrofayili yezinyo liba yigobe futhi ligobe ngemva kokuchama ngokudubula. Isilinganiso sobulukhuni ngemva kokuchama ngokushisa ngaphambi kokuchama sisetshenziselwa ukuchaza ukukhulisa ubulukhuni (Ithebula 3). Kungabonakala ukuthi ukukhulisa ubulukhuni kuhlukile ngaphansi kwezimo ezine zenqubo.

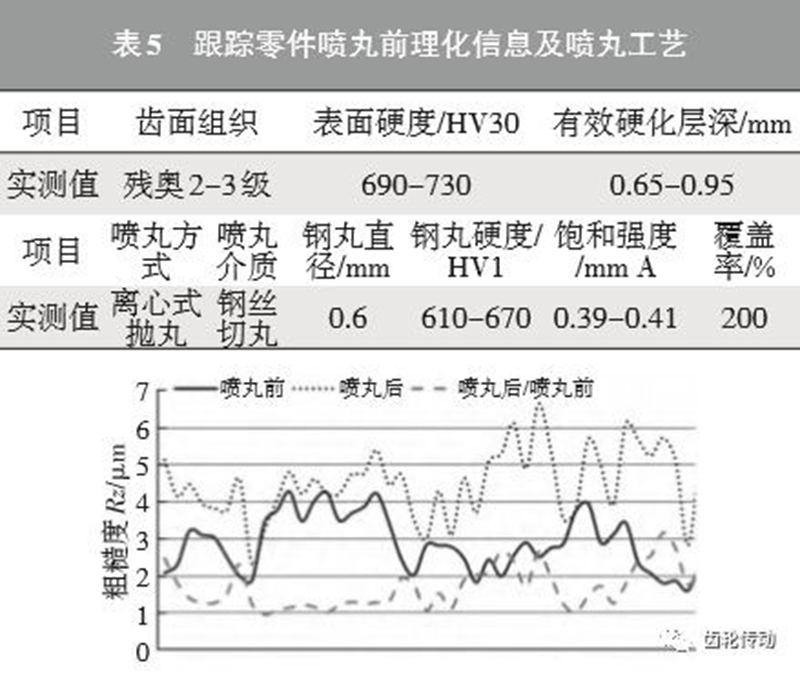

Ukulandelela Okubanzi Kokukhulisa Ubulukhuni Bomphezulu Wamazinyo Ngokukhipha Isibhamu

Imiphumela yokuhlolwa eseSigabeni 3 ikhombisa ukuthi ubulukhuni bobuso bezinyo buyanda ngamazinga ahlukahlukene ngemva kokuchama ngokudubula ngezinqubo ezahlukene. Ukuze kuqondwe ngokugcwele ukukhuliswa kokuchama ngokudubula ebulukhuni bobuso bezinyo nokwandisa inani lamasampula, kukhethwe izinto ezi-5, izinhlobo ezi-5 nezingxenye ezingama-44 sezizonke ukuze kulandelwe ubulukhuni ngaphambi nangemva kokuchama ngokudubula ngaphansi kwezimo zenqubo yokukhiqizwa kwe-batch yokuchama ngokudubula. Bheka Ithebula 5 ukuze uthole ulwazi olungokoqobo nolwamakhemikhali kanye nolwazi lwenqubo yokuchama ngokudubula lwezingxenye ezilandelwayo ngemva kokugaya igiya. Idatha yobulukhuni kanye nokukhulisa kwezingosi zamazinyo zangaphambili nangemuva ngaphambi kokuchama ngokudubula iboniswe ku-Fig. 4. Isibalo 4 sibonisa ukuthi ububanzi bobulukhuni bobuso bezinyo ngaphambi kokuchama ngokudubula buyi-Rz1.6 μ m-Rz4.3 μ m; Ngemva kokuchama ngokudubula, ubulukhuni buyakhula, kanti ububanzi bokusabalalisa buyi-Rz2.3 μ m-Rz6.7 μ m; Ubulukhuni obukhulu bungakhuliswa bube izikhathi ezingu-3.1 ngaphambi kokuchama ngokudubula.

Izici ezithonya ukugoba kobuso bezinyo ngemva kokuchama ngomjovo

Kungabonakala esimisweni sokuchama ngokudubula ukuthi ubulukhuni obukhulu kanye nokudubula okuhamba ngesivinini esikhulu kushiya imigodi eminingi ebusweni bengxenye, okuwumthombo wokucindezeleka okusele kokucindezela. Ngesikhathi esifanayo, le migodi nakanjani izokwandisa ubulukhuni bomphezulu. Izici zezingxenye ngaphambi kokuchama ngokudubula kanye nemingcele yenqubo yokuchama ngokudubula kuzothinta ubulukhuni ngemva kokuchama ngokudubula, njengoba kubalwe kuThebula 6. Esigabeni 3 saleli phepha, ngaphansi kwezimo ezine zenqubo, ubulukhuni bomphezulu wamazinyo ngemva kokuchama ngokudubula buyanda ngamazinga ahlukene. Kulesi sivivinyo, kuneziguquguquko ezimbili, okungukuthi, ubulukhuni bangaphambi kokudubula kanye nemingcele yenqubo (amandla okugcwala noma ukumbozwa), okungenakunquma ngokunembile ubudlelwano phakathi kobulukhuni bangemva kokudubula kanye nesici ngasinye esithonyayo. Njengamanje, izazi eziningi zenze ucwaningo ngalokhu, futhi zabeka imodeli yokubikezela yethiyori yobulukhuni bomphezulu ngemva kokuchama ngokudubula ngokusekelwe ekulingiseni kwe-finite element, esetshenziselwa ukubikezela amanani obulukhuni ahambisanayo ezinqubo ezahlukene zokuchama ngokudubula.

Ngokusekelwe kokuhlangenwe nakho kwangempela kanye nocwaningo lwezinye izazi, izindlela zethonya zezici ezahlukahlukene zingacatshangelwa njengoba kuboniswe kuThebula 6. Kungabonakala ukuthi ubulukhuni ngemva kokuchama ngokudubula buthintwa ngokuphelele yizici eziningi, okuyizici ezibalulekile ezithinta ukucindezeleka kokucindezela okusele. Ukuze kuncishiswe ubulukhuni ngemva kokuchama ngokudubula ngesisekelo sokuqinisekisa ukucindezeleka kokucindezela okusele, inani elikhulu lokuhlolwa kwenqubo liyadingeka ukuze kuqhutshekwe nokuthuthukisa inhlanganisela yamapharamitha.

Ithonya lokuqina kobuso bezinyo ekusebenzeni kwe-NVH kohlelo

Izingxenye zegiya zisesimisweni sokudlulisa esishintshashintshayo, futhi ubulukhuni bomphezulu wezinyo buzothinta ukusebenza kwazo kwe-NVH. Imiphumela yokuhlola ikhombisa ukuthi ngaphansi komthwalo nesivinini esifanayo, ubulukhuni bomphezulu bukhula, kulapho ukudlidliza nomsindo wesistimu kukhula khona; Lapho umthwalo nesivinini kukhuphuka, ukudlidliza nomsindo kuyanda ngokusobala.

Eminyakeni yamuva nje, amaphrojekthi emishini yokunciphisa amandla amasha akhuphuke ngokushesha, futhi abonisa ukuthambekela kokuthuthuka kwesivinini esikhulu kanye ne-torque enkulu. Njengamanje, i-torque ephezulu ye-energy reducer yethu entsha ingu-354N · m, kanti isivinini esiphezulu siyi-16000r/min, esizokhushulwa sibe ngaphezu kuka-20000r/min esikhathini esizayo. Ngaphansi kwezimo zokusebenza ezinjalo, ithonya lokwanda kokuqina kobuso bamazinyo ekusebenzeni kwe-NVH kohlelo kumele licatshangelwe.

Izindlela zokuthuthukisa ukugoba kobuso bamazinyo ngemva kokuchama ngomjovo

Inqubo yokuchama ngemva kokugaya igiya ingathuthukisa amandla okukhathala kokuthintana kwendawo yezinyo legiya kanye namandla okukhathala okugoba kwempande yezinyo. Uma le nqubo kumele isetshenziswe ngenxa yezizathu zamandla enkambisweni yokuklama igiya, ukuze kucatshangelwe ukusebenza kwe-NVH kohlelo, ubulukhuni bendawo yezinyo legiya ngemva kochama ngemva kokudubula kungathuthukiswa kusukela kulezi zici ezilandelayo:

a. Lungiselela amapharamitha enqubo yokuchama kwezinyo, bese ulawula ukukhuliswa kobukhali bomphezulu wezinyo ngemva kokuchama kwezinyo ngesisekelo sokuqinisekisa ukucindezeleka okusele kokucindezela. Lokhu kudinga ukuhlolwa okuningi kwenqubo, futhi ukuguquguquka kwenqubo akunamandla.

b. Inqubo yokuchama ngokudubula okuhlanganisiwe iyasetshenziswa, okungukuthi, ngemva kokuba ukuchama ngokudubula okunamandla avamile sekuqediwe, kufakwa okunye ukuchama ngokudubula. Amandla enqubo yokuchama ngokudubula andayo ngokuvamile mancane. Uhlobo nosayizi wezinto zokudubula kungalungiswa, njengesithombe se-ceramic, isithombe sengilazi noma isithombe sensimbi esinqunyiwe ngocingo esinosayizi omncane.

c. Ngemva kokuchama ngomjovo, kunezelwa izinqubo ezifana nokupholisha ubuso bamazinyo kanye nokulolongwa kwamahhala.

Kuleli phepha, kufundwa ubulukhuni bobuso bezinyo bezimo ezahlukene zenqubo yokuchama ngomjovo kanye nezingxenye ezahlukene ngaphambi nangemva kokuchama ngomjovo, futhi iziphetho ezilandelayo zitholwa ngokusekelwe ezincwadini:

◆ Ukuchama ngomjovo kuzokwandisa ubulukhuni bomphezulu wezinyo, okuthintwa izici zezingxenye ngaphambi kokuchama ngomjovo, imingcele yenqubo yokuchama ngomjovo nezinye izici, futhi lezi zici nazo ziyizici ezibalulekile ezithinta ukucindezeleka okusele kokucindezela;

◆ Ngaphansi kwezimo zenqubo yokukhiqiza i-batch ekhona, ubulukhuni obukhulu bomphezulu wamazinyo ngemva kokuchama ngokudubula buphindwe izikhathi ezingu-3.1 kunangaphambi kokuchama ngokudubula;

◆ Ukwanda kokuqina kobuso bezinyo kuzokwandisa ukudlidliza nomsindo wesistimu. Uma i-torque nesivinini kukhulu, kulapho kusobala khona ukwanda kokudlidliza nomsindo;

◆ Ubulukhuni bomphezulu wezinyo ngemva kokuchama ngokudubula bungathuthukiswa ngokwenza ngcono amapharamitha enqubo yokuchama ngokudubula, ukuchama ngokudubula okuhlanganisiwe, ukwengeza ukupholisha noma ukucija ngokukhululeka ngemva kokuchama ngokudubula, njll. Ukulungiswa kwamapharamitha enqubo yokuchama ngokudubula kulindeleke ukuthi kulawule ukukhuliswa kobulukhuni kube cishe izikhathi ezingu-1.5.

Isikhathi sokuthunyelwe: Novemba-04-2022