Ukuthola izinto ezifanele kakhulu zamagiya

Lapho kuklanywa futhi kukhiqizwa amagiya, izinto ezisetshenziswayo zizoncika ekutheni hlobo luni lwegiya olukhiqizwayo nokuthi luzosetshenziswa kanjani futhi kuphi.

Kunezinhlobo eziningi zezinto zokusetshenziswa ezivame ukusetshenziswa ezakhiweni zamagiya, futhi into ngayinye inezakhiwo zayo ezinhle kakhulu zemishini futhi iyisinqumo esingcono kakhulu.Izigaba eziyinhloko zezinto zokwakha yi-alloys zethusi, i-alloys yensimbi, i-alloys ye-aluminium kanye ne-thermoplastics.

1. Ingxube yethusi

⚙️Niniukuklama igiyaokuzobhekana nendawo egqwalisayo noma okudingeka ingabi namandla kazibuthe, ingxube yethusi ngokuvamile iyona engcono kakhulu.

⚙️Izinhlobo ezintathu ezivame kakhulu zethusi ezisetshenziswa kumagiya yithusi, ithusi le-phosphor, kanye nethusi le-aluminium.

⚙️Amagiya avame ukwenziwa nge-alloy yethusiamagiya okucindezelakanye nama-racks futhi kuzosetshenziswa ezindaweni ezithwala umthwalo omncane.

⚙️Ithusi le-phosphorus lithuthukisa ukumelana nokuguguleka kanye nokuqina kwe-alloy. Ukugqwala okuphezulu kanye nokumelana nokuguguleka kwenza ama-alloy ethusi le-phosphor abe yisinqumo esihle kakhulu sezingxenye ze-friction drive ephezulu. Isibonelo:igiya lezibungu

⚙️Ithusi le-aluminium liyingxube yesithathu yethusi esetshenziswa kumagiya. Ama-alloy ethusi le-aluminium anokumelana nokuguguleka okuphezulu kune-alloy ethusi le-phosphor futhi anokumelana nokugqwala okuphezulu. Amagiya ajwayelekile akhiqizwa ngama-alloy ethusi le-aluminium afaka amagiya e-helical ahlanganisiwe (amagiya e-helical) kanye namagiya e-worm.

2. Izinsimbi zensimbi

⚙️Umaumklamo wegiyaidinga amandla aphezulu ezinto ezibonakalayo, ama-alloy ensimbi ayisinqumo esingcono kakhulu. Uma isesimweni sayo esiluhlaza, insimbi empunga ingaphonswa futhi ifakwe emishinini.

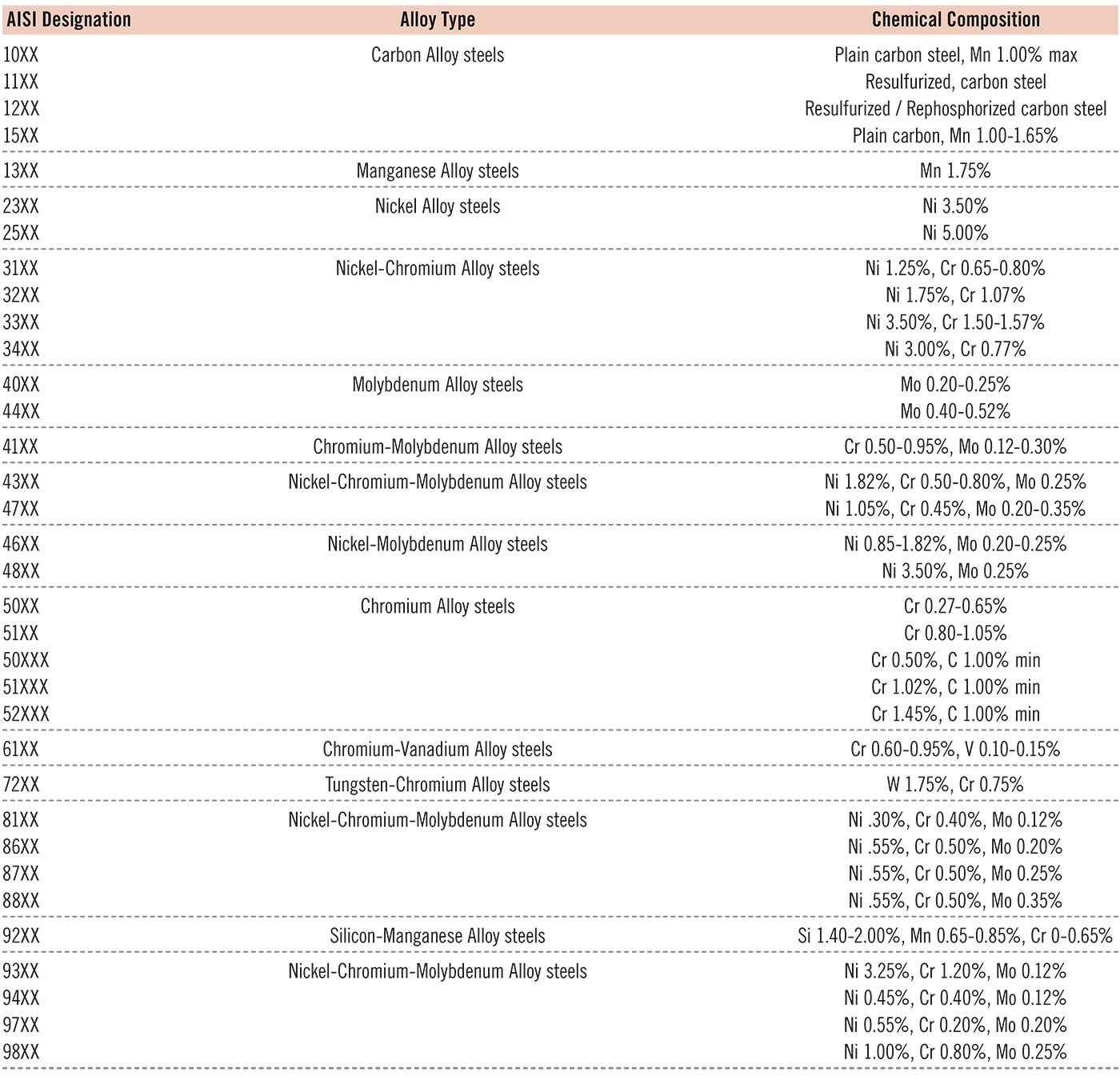

⚙️Kunezinhlobo ezine eziyinhloko ze-alloy yensimbi: insimbi yekhabhoni, insimbi ye-alloy, insimbi engagqwali, kanye nensimbi yamathuluzi. Ama-alloy ensimbi yekhabhoni asetshenziswa cishe kuzo zonke izinhlobo zegiya ngoba kulula ukuwafaka emshinini, anokumelana okuhle nokuguguleka, angaqiniswa, atholakala kabanzi, futhi ashibhile kakhulu.

⚙️Izinsimbi zensimbi zekhabhoni zingahlukaniswa kabanzi ngensimbi ethambile, insimbi yekhabhoni ephakathi nendawo, kanye nensimbi yekhabhoni ephezulu. Izinsimbi zensimbi ethambile zinokuqukethwe kwekhabhoni okungaphansi kuka-0.30%. Izinsimbi zensimbi zekhabhoni ephezulu zinokuqukethwe kwekhabhoni okungaphezu kuka-0.60%, kanti izinsimbi zekhabhoni ephakathi nendawo ziphakathi nendawo. Lezi zinsimbi ziyisinqumo esihle sazoamagiya okucindezela, amagiya ajikelezayo, ama-reck egiya,amagiya e-bevel, kanye nezimpethu.

3. Ama-alloy e-aluminium

⚙️Ama-alloy e-aluminium ayindlela enhle esikhundleni sama-alloy ensimbi ezisetshenziswayo ezidinga isilinganiso samandla aphezulu nesisindo. Ukuphela kobuso okwaziwa ngokuthi i-passivation kuvikela ama-alloy e-aluminium ekungcolisweni nasekugqwaleni.

⚙️Ama-alloy e-aluminium awakwazi ukusetshenziswa ezindaweni ezishisa kakhulu njengoba eqala ukuguquka ku-400°F. Ama-alloy e-aluminium avamile asetshenziswa ekugiyeni yi-2024, 6061, kanye ne-7075.

⚙️Zonke lezi zinhlobo ezintathu ze-aluminium alloys zingalungiswa ngokushisa ukuze kuthuthukiswe ubulukhuni bazo. Amagiya enziwe nge-aluminium alloys afaka phakathiamagiya okucindezela, amagiya ajikelezayo, amagiya e-bevel amazinyo aqondile, kanye nama-gear racks.

4. Ama-thermoplastic

⚙️Ama-thermoplastic ayisinqumo esingcono kakhulu samagiya lapho isisindo siyinqubo ebaluleke kakhulu. Amagiya enziwe ngamapulasitiki angashintshwa ngomshini njengamagiya ensimbi; noma kunjalo, amanye ama-thermoplastic afaneleka kangcono ekukhiqizweni ngokufaka i-injection molding. Enye ye-injection molded thermoplastic evame kakhulu yi-acetal. Le nto yaziwa nangokuthi (i-POM). Amagiya angenziwa nganoma iyiphi i-polymer. Lawa angenziwaamagiya okucindezela, amagiya ajikelezayo, amasondo ezikelemu, amagiya e-bevel, kanye nama-gear racks.

Isikhathi sokuthunyelwe: Julayi-13-2023