Ama-Cement Vertical Roller Mills ayizingxenye ezibalulekile ohlelweni lokugaya izinto ezingavuthiwe zibe usimende, futhi ukusebenza kahle kwalezi zigayo kuncike kakhulu kwikhwalithi nokunemba kwezingxenye zazo ezibalulekile, ikakhulukazi amagiya e-spiral bevel.

Amagiya e-spiral bevel asho amagiya anejiyomethri yezinyo eyingqayizivele evumela ukudluliswa kwamandla okubushelelezi nokusebenza kahle.Lawa magiya akhelwe ngokukhethekile ukusingatha imithwalo esindayo kanye nezimo zokusebenza eziguquguqukayo okuhlangabezana nazo embonini kasimende.Inqubo yokukhiqiza la magiya ihlanganisa ubunjiniyela obunembayo, ukukhanda ngobunyoninco, kanye nezinyathelo eziqinile zokulawula ikhwalithi ukuze kuqinisekiswe ukuthi amagiya ahlangabezana nezindinganiso ezidingekayo ukuze asetshenziswe.

Umsebenzi oyinhloko wala magiya ukudlulisa amandla esuka kumshini wokugaya uwayise etafuleni lokugaya, lapho izinto ezingavuthiwe zicutshungulwa zibe yimpushana.Amagiya e-spiral bevel anika amandla isigayo se-roller esime mpo ukuthi sisebenze kahle kakhulu, sinikeza itorque edingekayo kanye nesivinini sokujikeleza sokugaya okusebenzayo.Ngenxa yezimo ezinzima zokusebenza ezigayweni zikasimende, okuhlanganisa imithwalo ephezulu, ukudlidliza, namazinga okushisa aphakeme kakhulu, amagiya kufanele abe namandla futhi aqine ukuze kuqinisekiswe ukusebenza okuthembekile nokuqhubekayo.

Hlobo luni lwemibiko ezonikezwa amakhasimende ngaphambi kokuthunyelwa ukuze kugaywe amagiya amakhulu e-spiral bevel ?

1) Umdwebo webhamuza

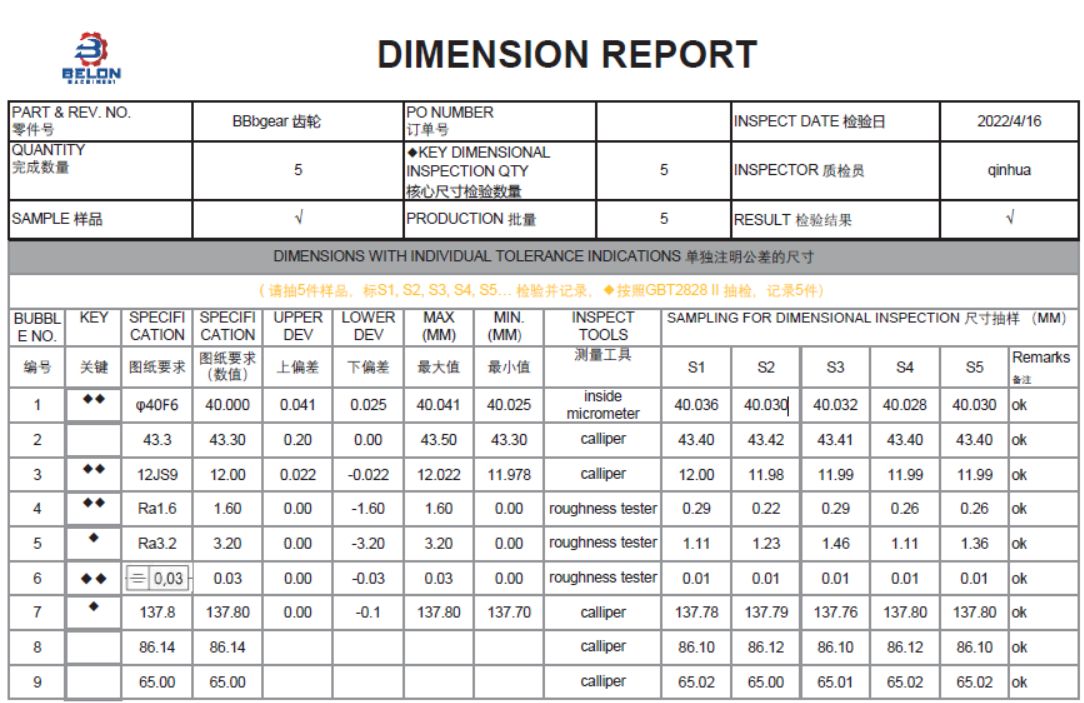

2) Umbiko wobukhulu

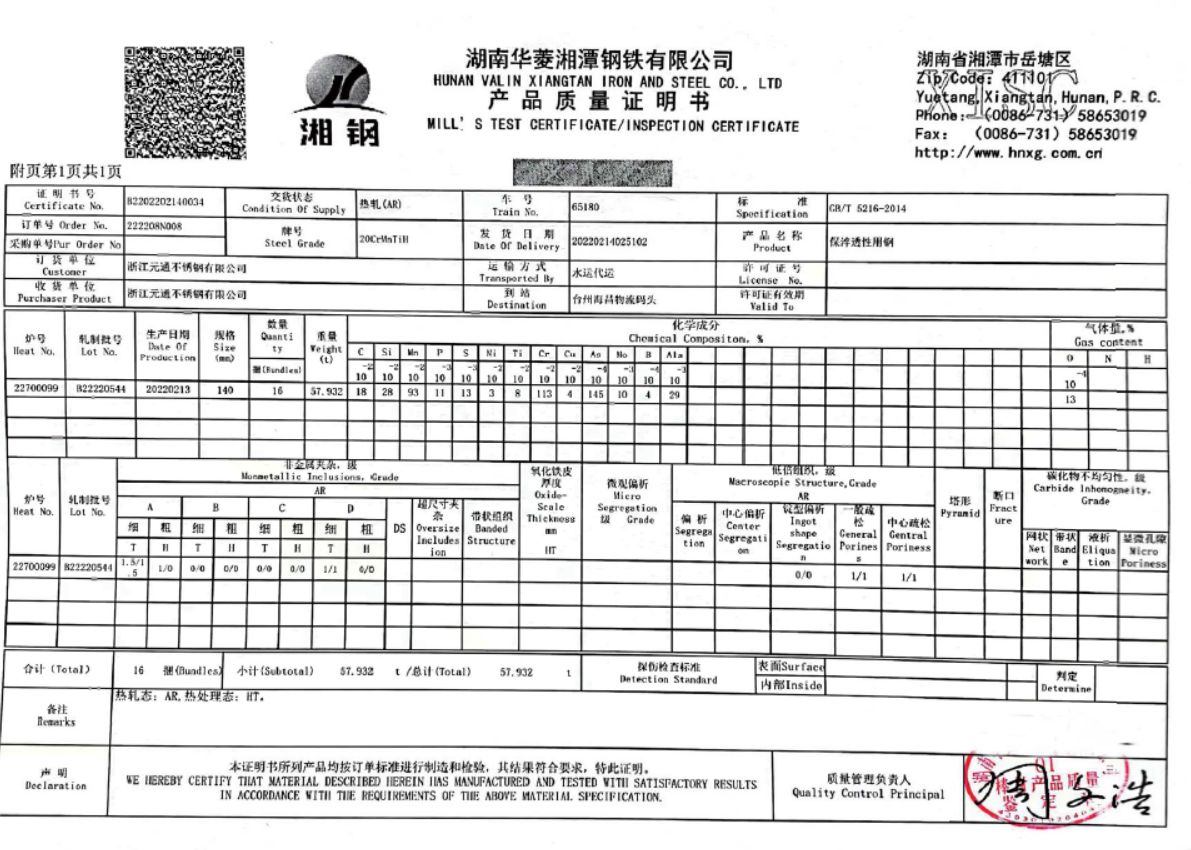

3) Isitifiketi sezinto ezibonakalayo

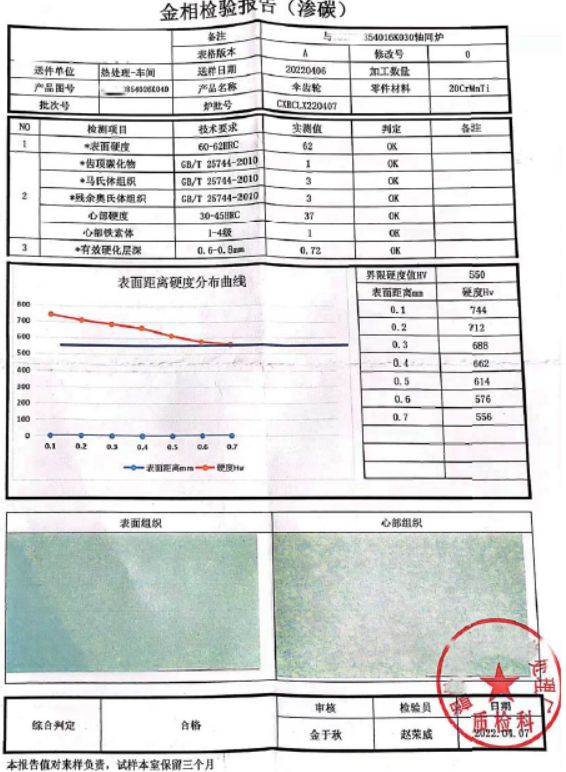

4) Umbiko wokuphatha ukushisa

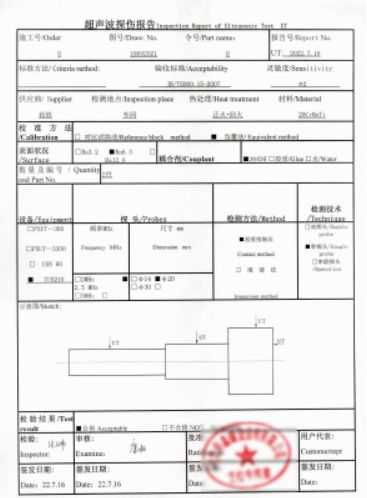

5) Umbiko wokuhlolwa kwe-Ultrasonic (UT)

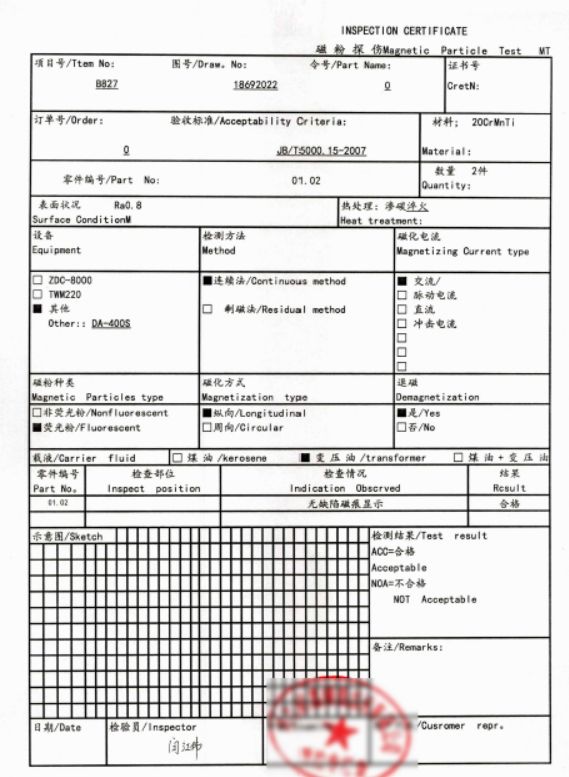

6) Umbiko wokuhlolwa kwe-Magnetic Particle (MT)

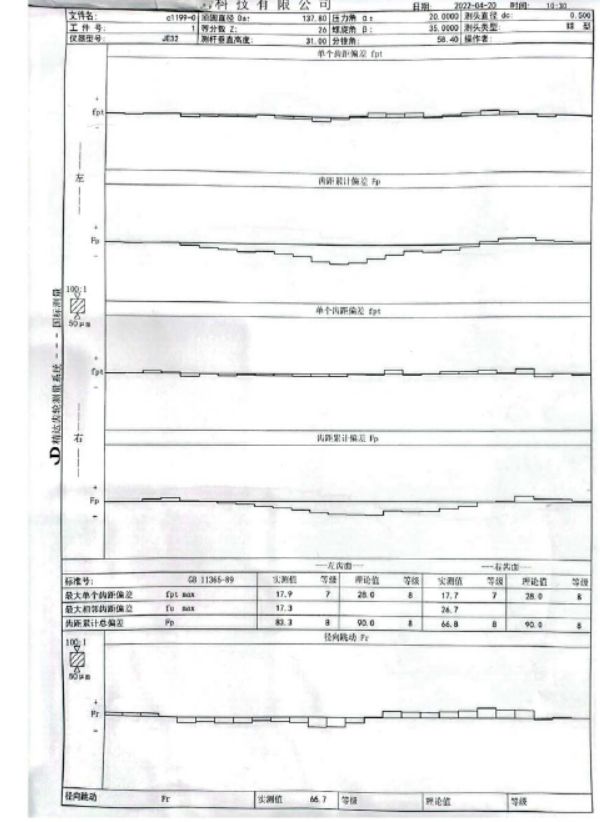

Umbiko wokuhlola we-Meshing

Sixoxa indawo engamamitha-skwele angu-200000, futhi efakwe kusengaphambili ukukhiqiza kanye nemishini yokuhlola ukuhlangabezana nesidingo samakhasimende.Sethule usayizi omkhulu kunayo yonke, isikhungo sokuqala semishini sase-China esiqondene ngqo negiya i-Gleason FT16000 selokhu kwaba nokubambisana phakathi kwe-Gleason ne-Holler.

→ Noma Yimaphi Amamojula

→ Noma yiziphi Izinombolo Zamazinyo

→ Ukunemba okuphezulu kwe-DIN5

→ Ukusebenza kahle okuphezulu, ukunemba okuphezulu

Ukuletha ukukhiqiza kwephupho, ukuguquguquka kanye nomnotho weqoqo elincane.

impahla eluhlaza

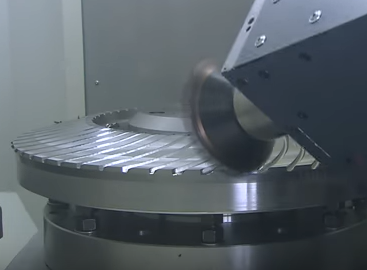

ukusika rough

ukuphenduka

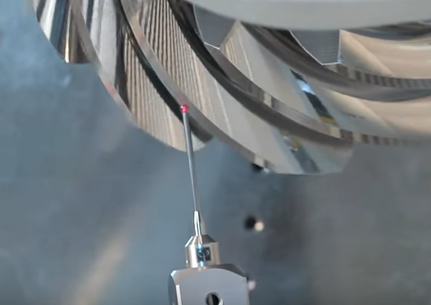

ukuphefumula nokuphefumula

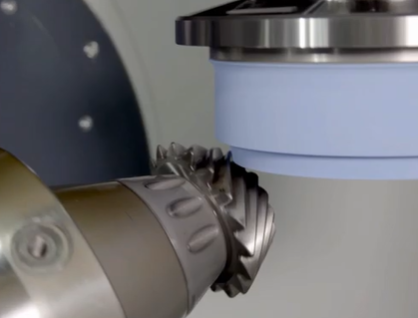

ukugaya amagiya

Ukuphatha ukushisa

ukugaya amagiya

ukuhlola